David, this won't really help you, but it might help someone sometime. Use the concept for lock plate duplicating, or lock inlets, or whatever you turn your little minds to. Keep you off the street for a few hours.

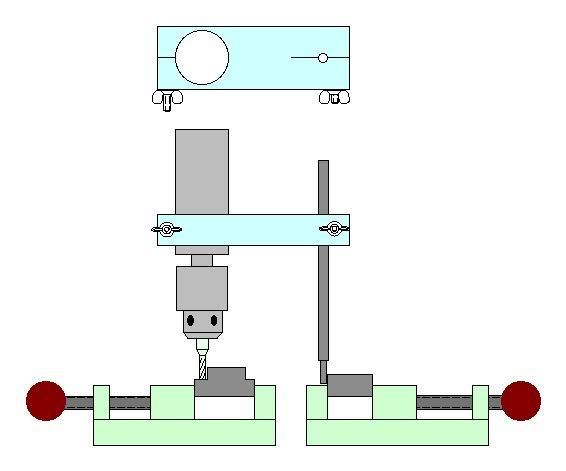

For this, you need a lathe and a mill.

The concept of a duplicator. the mill spindle is on the left, and a trace arm is connected by a bar on the right.

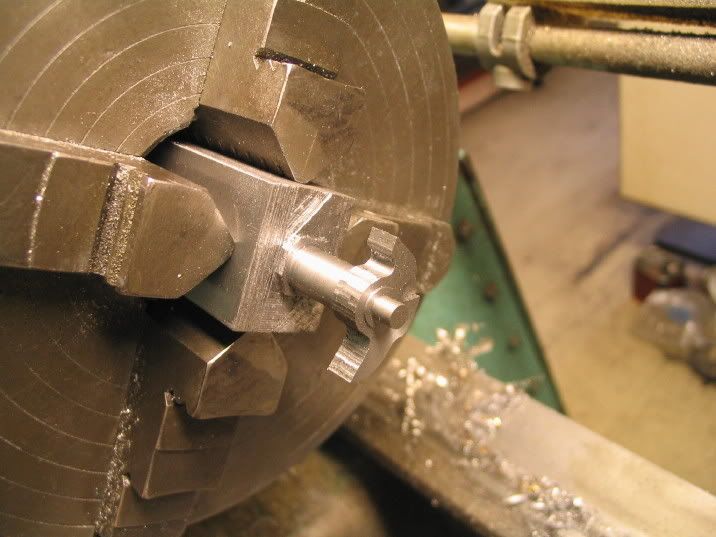

In practice, tracing carefully around the original tumbler

Image of the near complete tumbler, workpiece on the left, original on the right.

Turning the shank after the milling is done.