Guys,

Here is a method to make a replacement screw for a lost original that does not correspond to a modern thread. For this tutorial we will be using an old Jos Golcher lock plate, notice three mainspring pin holes and three sear spring slots - a lot of use here. First whittle a wood pin to twist into the screw hole, I usually leave the pin a rough octagon shape. Twist the pin in & out a few times so that the thread outer diameter and the pitch are marked on the wood.

Then take a careful measurement of the wood "thread" diameter and pitch. In this case a 0.150 O.D. x 36 TPI.

Here is where it get a a bit difficult for many of us. I find a thread on a thread plate that matches the pitch TPI closely and matches or exceeds the O.D. This is the one I used, a early 19th C thread plate marked "CB".

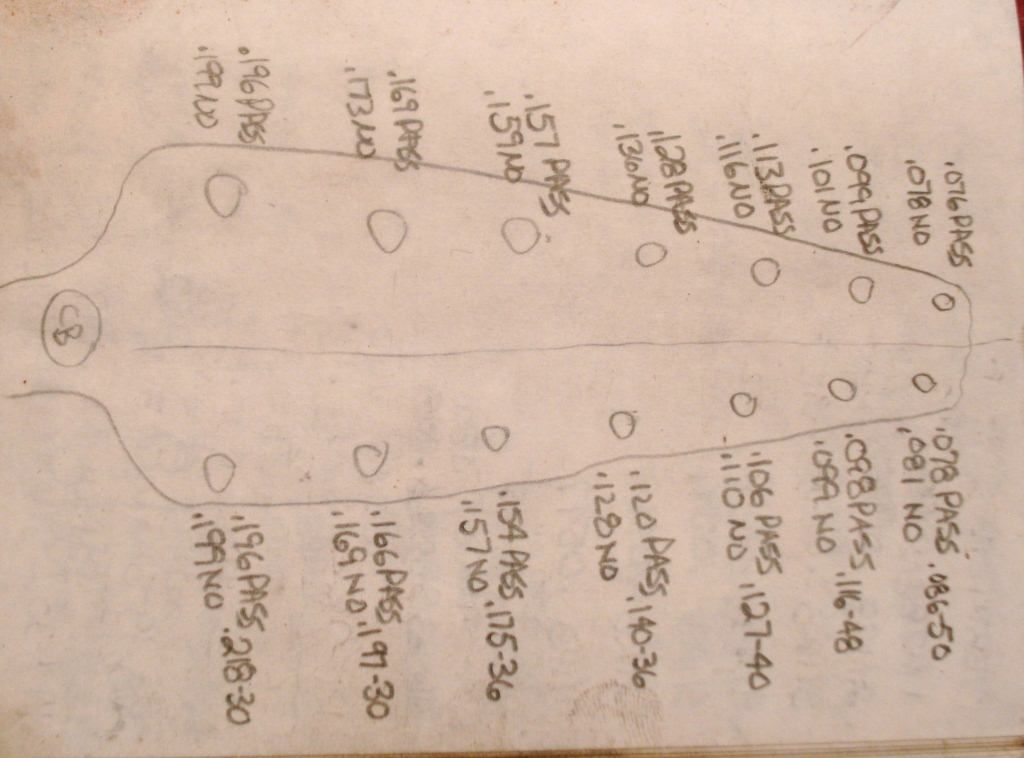

This is a page from my field notebook, the thread in the plate will make a 0.175 x 36 thread. A good match for the thread TPI, just a bit too large in diameter.

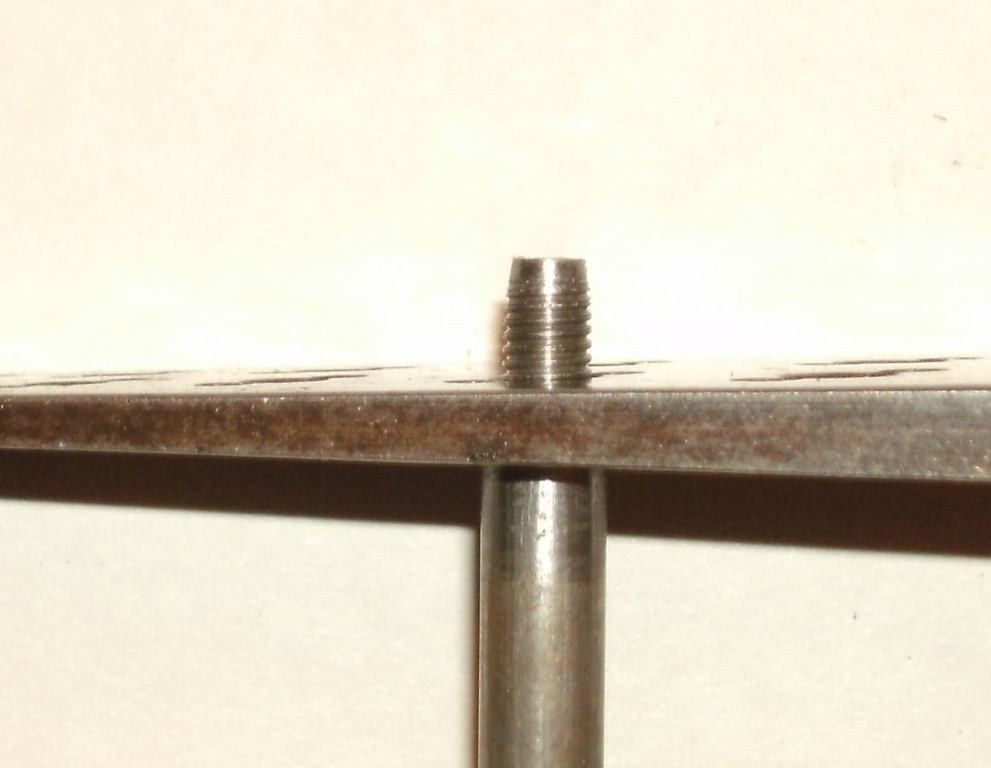

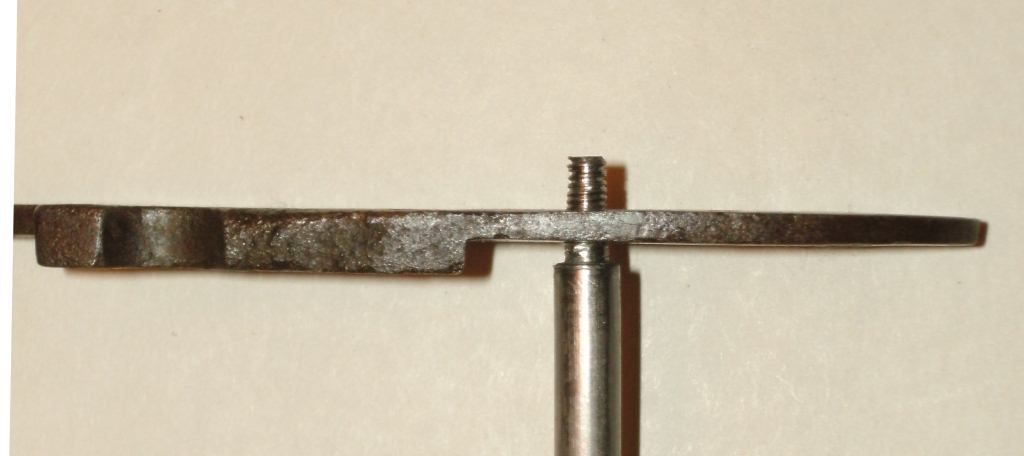

I turn a pin to 0.160 diameter and thread the pin. The early threads look a lot like lightbulb threads rather than modern UNC/UNF type threads.

Now the thread diameter is reduced using a tiny triangular file. The file follows easily along the existing thread form to reduce the diameter while not changing the pitch. A bit tedious, but not difficult.

Eventually, with a lot of fit - file - fit - file, the new screw will mate very well with the existing odd sized thread and there you have a replacement screw. It measures 0.148 x 36.

Jim