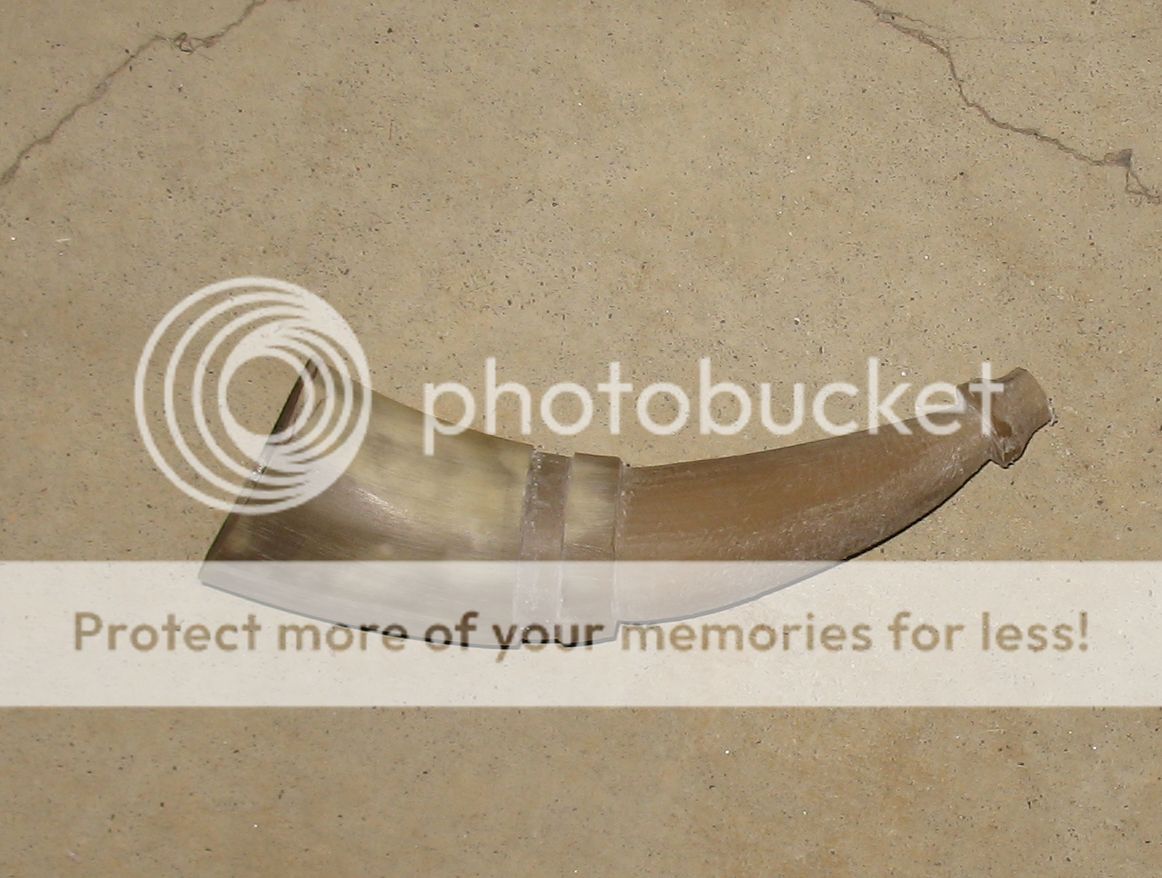

This is a takeoff of the thread Hubu started; Banded Horns: observations and questions. It is a horn I started at a living history event. While I was working on it I filed though the neck at one spot, so it was either trash it, cut it into bands of repair it. Repair it was to try and demonstrate a point, that the everyday guy using his ingenuity could have fixed the cracked or broken tip on his horn.

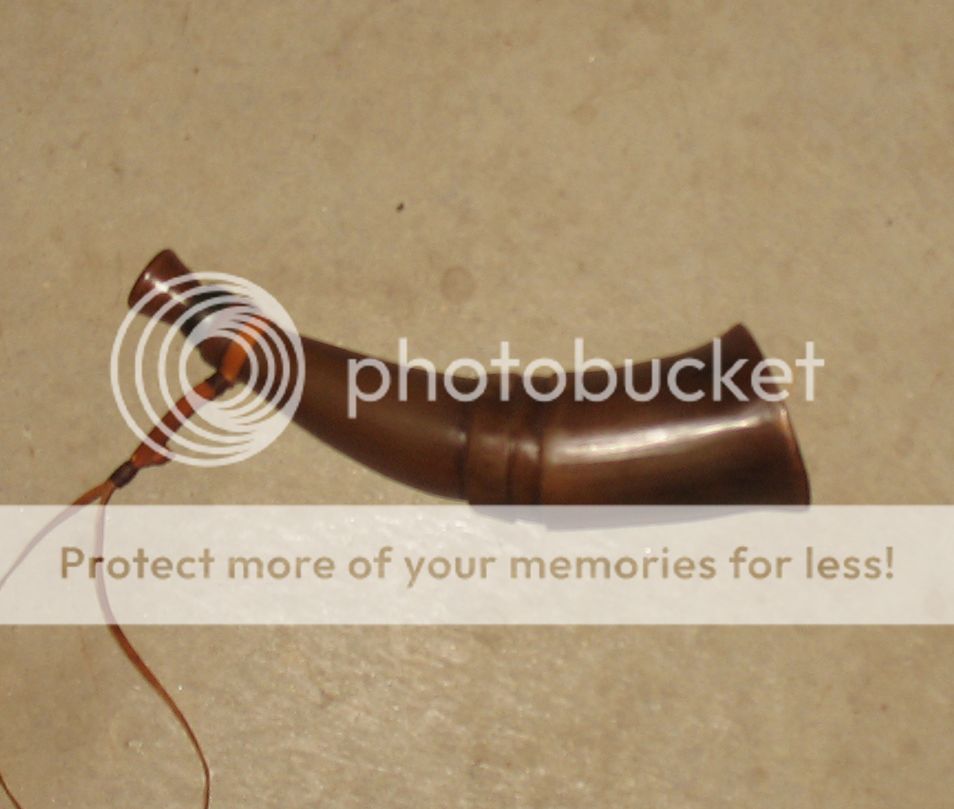

Once the repair was finished I decided to make the horn into a pocket hunting horn, it is small, about 9” but has a good sound. I shaped and thinned it out quite a bit at the base. The mouth piece is horn and pressed in, the band at the Pewter is applied, the other is part of the horn, tried to give it a little flare at the base.

Tim C.

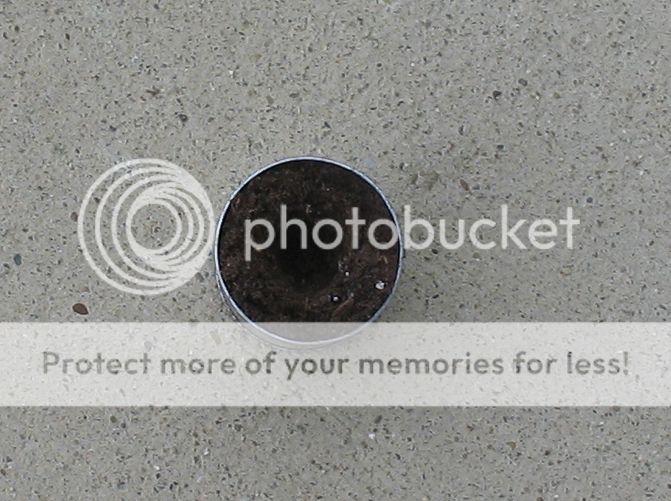

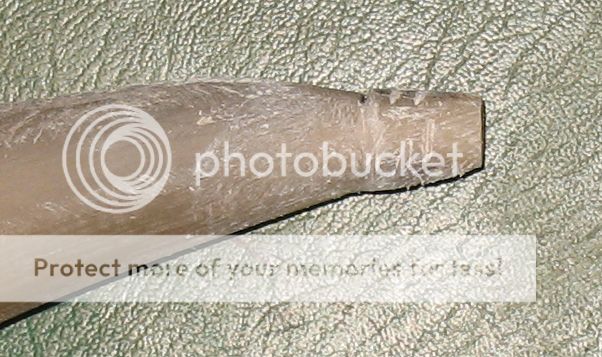

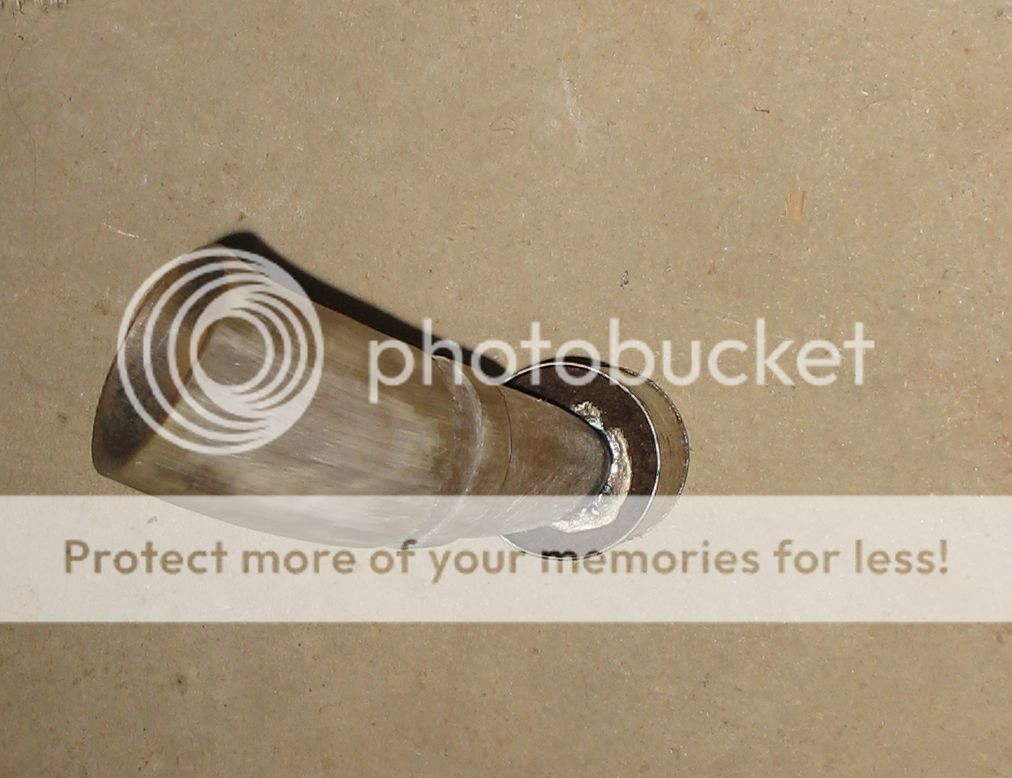

Think about it, the tip on your horn is broken off or cracked what to do, hmm. How about this; I have a ladle/spoon that I melt lead in to make balls and some of those balls in my pouch. So I take my knife, reshape the tip, cut a couple of groves at the tip, carve a stick about 3 inches long that will fit tightly in the spout and put it in leaving about half sticking out. Using you index finger poke a hole in the ground about the depth of it, take the horn with the stick in it and push the stick down in the center of the hole until the horn tip is just above or barely touching the bottom of the hole. Now melt a few balls in the spoon and pour into the hole, let it cool.

Pull it out of the ground and you have a very rough casting on the horn with a stick in it, remove the stick and using your knife shape the tip, use a piece of stone as a file to finish.

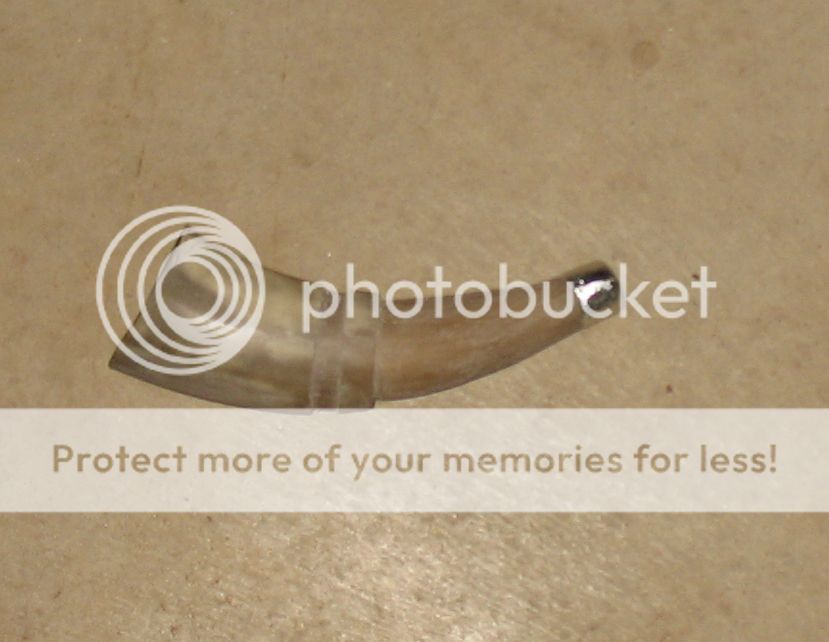

Here is the one I tried, not perfect but functional. Took about 30 minutes. It’s raining out so I used a can with dirt in it 1st pic, 2nd is of the broken tip, 3rd shaped down, 4th Stick, 5th Horn in can with Pewter poured, 6th rough right out of dirt, 7th after some shaping.

Tim C.