Tools for installing rod pipes: the aluminum bar at back (from a patio door) I use to rub in the rod groove and on the lips of the groove to check for high spots. Cut the groove level with a rounded scraper (made from a screwdriver), a rattail file, or a dowel with sandpaper. The lips are trued up with a long sanding block. The white rod is a 3/8" fiberglass electric fence post, used in aligning. The drill is a 25/64" bit brazed on a 3/8" steel rod from True Value. Or it can be tongue-and-grooved and pinned. The shank of the bit is not hard. When aligned straight, solder the joint. Will show this in my next show on nose caps. I use this to drill the hole back to the tang screw. The 3/8" chisel I use to inlet the pipes, and the 1/16" one, made from a screwdriver, I use to cut the tab slots. Sheet rock nails make good pins, and here I use motorcycle spokes, .093. The steel guide is a piece of 1/8" angle iron with guide holes drilled so the bit just clears the bottom of the barrel for the underlug staple, or just hits the center of the rod pipe tab. 1.580 is from the top of the barrel to the bottom of the entry pipe, less .500 to drill the center of the tab. I used a No. 42, .0935. Small drills, such as 1/16", bend easily so I use at least a .070, sheet rock nails are .094.

Here a pipe is inletted upside down, then the tab slot is cut with chisels. The tab is cut to just hold a pin. Better to slant the ends up to the center, those corners are hard to cut and not needed. Inlet the pipe flush so a rod slides through. The rattail file can true up if needed.

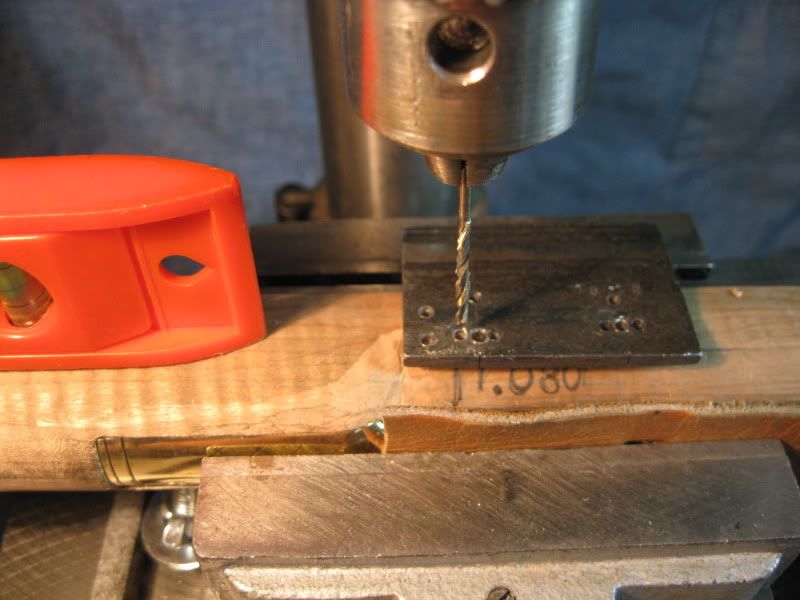

Drilling the stock and tab. Never Fail! Notice the entry pipe stock was .030 thicker.

For the entry pipe, inlet an upper pipe first, tab and all. Then the skirt. Draw straight lines on the forend to keep it straight.

Here I smoke up the skirt for fitting. Paint thinner works good. Keep the skirt parallel to the rod.

Measure how wide the skirt is. It will spread in tapping in. It is easily bent in a vise, and in fact I sometimes bend the skirt to a smaller radius before starting.

Drilling the entry pipe pin hole. The leather squeezes the entry pipe level into the stock. If the entry pipe skirt is not deep engough, a rod will not slide into the hole. The deep hole drill can help, but so can the rattail file. The skirt and front of the trigger guard set the line for the belly of the lower forend, a straight line.

I use that aluminum bar for truing up the stock flats. Will show some of that next time.