Guys,

This is a continuation of the subject of barrel straightening from the subject of sight adjustment in the shooting section. First, a warning - please don't read this section and then go hitting the new Getz barrel with an 8 pound sledge! Even though this may make the artists cringe, this is how I straighten a forged wrought iron barrel.

During the hot forging process I straighten the barrel until I can see light through the bore. This is done by eye using an 8 pound sledge on a large anvil. The two subsequent straightenings shown below are done cold.

After the initial straightening the gun bore is reamed out with a succession of square reamers followed by a honing with an armory reamer. This leaves the bore very smooth and shiny. I look through the bore at a line drawn on the wall of my shop, looking at the reflection of the line on the bore wall. Usually the reflected line is curved. I straighten the barrel until the reflected line appears to be straight, or as straight as my old eyes can see. I place the rough forged barrel on the anvil surface with two spacers. I hammer the barrel with an 8 pound sledge between the spacers to straighten. The spacers limit the possible movement of the barrel to prevent over bending. After straightening I finish the barrel outside and rifle the bore (if making a rifle).

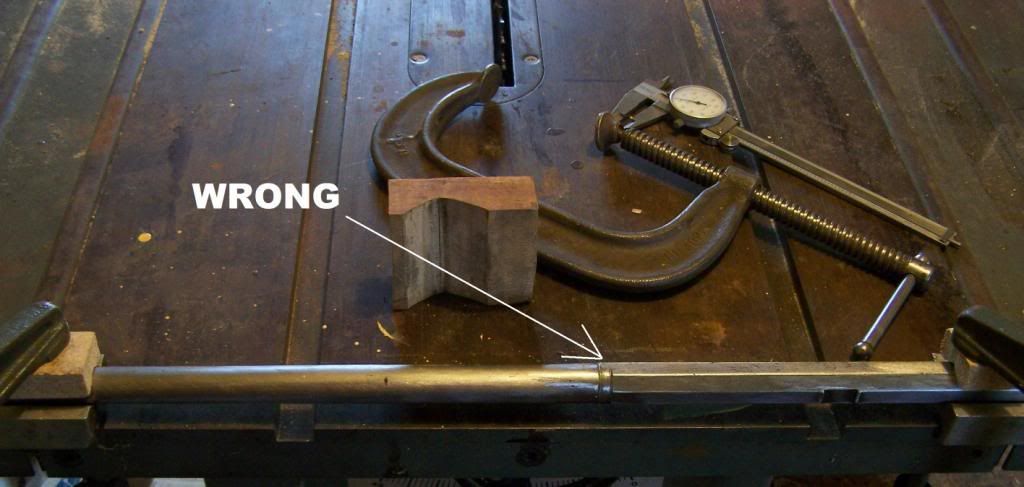

After the gun is finished I shoot the gun to set the sights. Leaving the front sight too high I file it down until I get the bullet hitting about 2" high at 25 yards. If the bullet is hitting too far left/right I again straighten (or bend) the barrel to bring the bullet in line with the sights. I clamp the barrel on the top platen of my table saw using my post vice removable jaws as vee blocks. I match mark everything with a pencil so I can realign everything if the setup shifts.

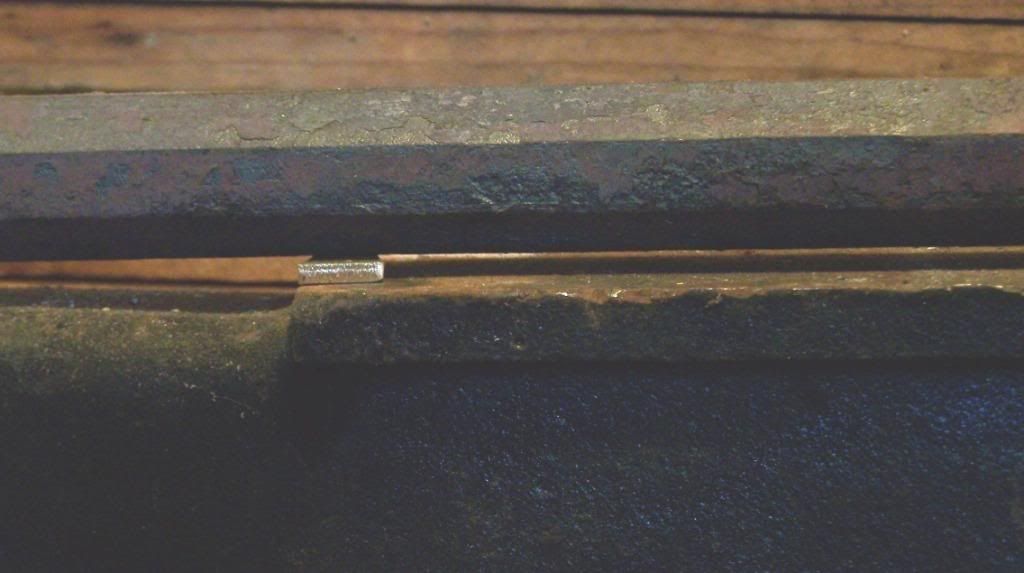

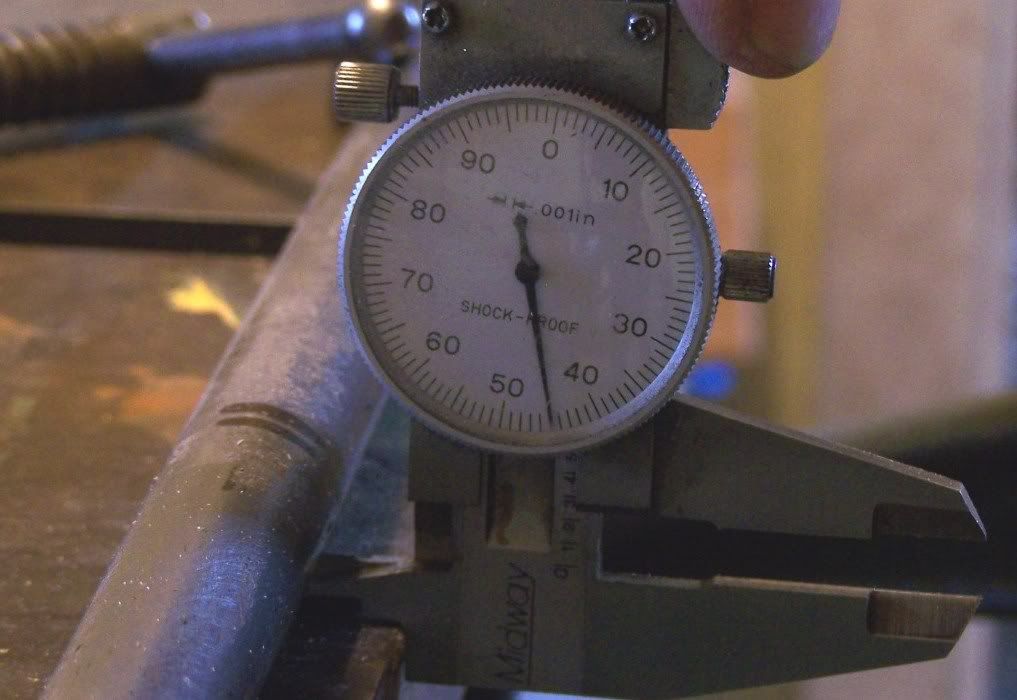

I mark the center of the barrel as shown to position a dial caliper at the same spot for measurements. Then I measure from the barrel down to the platen surface, in this case 0.245. This is a 38" oct/rnd wrought iron barrel, 0.42 caliber, smoothbore.

I then tighten a clamp on the barrel in the center between the vee blocks and flex the barrel slightly, then relax the clamp. I repeat the measurement, normally finding no change in the measurement at all. I do subsequent clampings and barrel flexings, each time tightening the clamp a little more than the last trial. I try to remember the clamp handle position from the last time and tighten it about 5 degrees more each time.

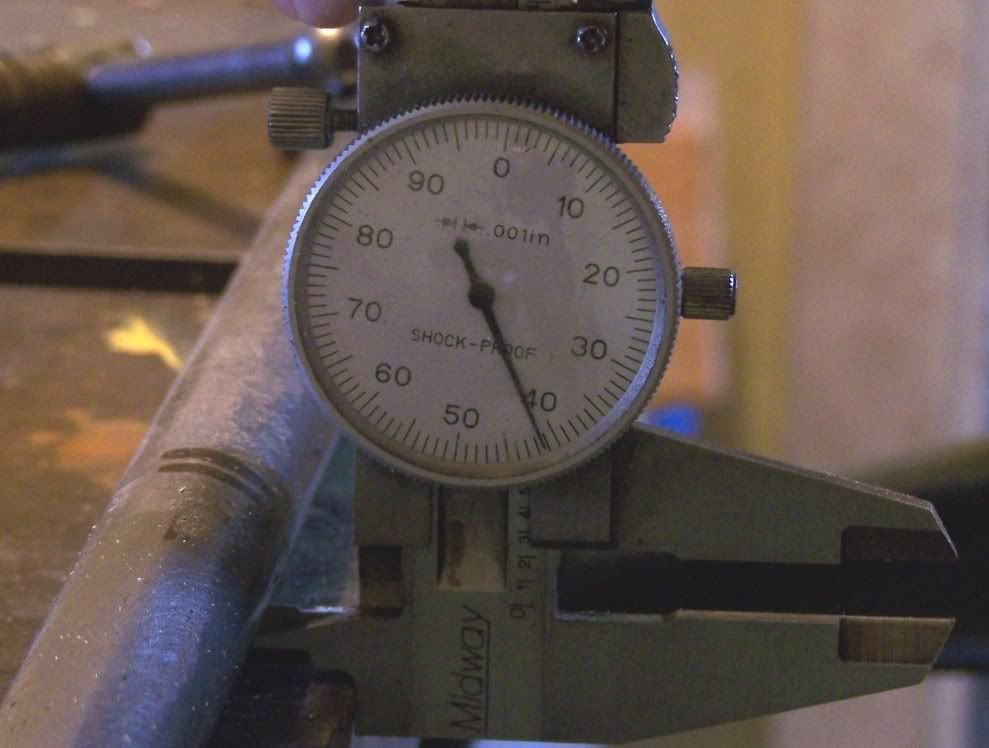

Eventually my measurement will show a tiny bit of permanent set to the barrel, meaning that I have bent the barrel in the direction I wish to put the bullet impact in line with the sights. In this case the dial caliper now measures 0.242, or a bend on 0.003 in an 18" span. This is about 1 sheet of paper thickness, you cannot see it by eye.

Now reassemble the gun and back to the range to see the result. Often it takes two or three cycles of barrel straightening (or bending) until be bullet holes begin to behave themselves. I am sure that the great artists on this site will think me a bit nuts for bending barrels, but making wrought iron barrels can be downright violent when compared to beautiful and delicate woodcarving and engraving.

P.S. Do not straighten a barrel over the oct/rnd transition or any other abrupt change in the barrel dimensions as the bend will tend to concentrate or kink at that spot.

Jim Everett