I didn't see anything in the tutorial section about this, so I thought it might be helpful to some of our newer members. I'm currently building a fowler and needed to move a lug as it had some placement problems with the trigger plate. You could also use this method to replace a lug that needs to be longer...

first, the lug that needs to be moved or replaced is cut off from the trigger guard

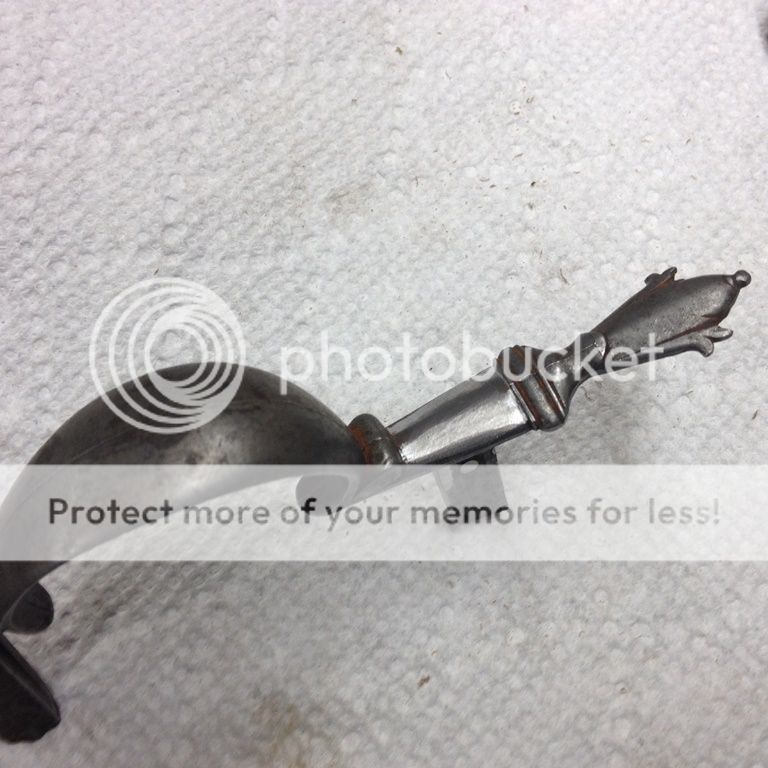

Next, a shoulder is filed on the replacement lug

A hole is then drilled in the trigger guard, roughly shaped with a jewelers saw, then filed to fit the lug. A bevel is then filed on the top edge of this opening.

The tab on the new lug is then peened into the beveled opening in the trigger guard

Lastly, the lug is filed smooth with the trigger guard.

This is a simple fix to a fairly common problem, and I feel superior to silver soldering.

Ed