Here is a copy of the information we have about what makes a quality flintlock. Perhaps Dad will elaborate on this soon.

THE QUALITY FLINTLOCK

There are features common to all flintlocks which must be present if the lock is to be reliable, consistent from shot to shot, and long lasting.

A.

Exterior Geometry- 1. Cock throw (the distance from the center of the square tumbler hole to the lower jaw) this distance should be equal to or slightly longer than the distance from the center of the tumbler hole to the face edge of the closed frizzen.

- 2. Angle of the Jaws The line of the lower jaw should intersect the pan just forward of the pan center.

- 3. Frizzen Spring Screw Should be under frizzen pivot. This has more to do with aesthetics than with function.

- 4. Center of Tumbler Should be on midline of the lockplate.

- 5. Frizzen Spring There should be minimal space between the upper and lower leafs. The upper leaf should be almost straight, or it should have a slight hump bent into it. Be sure to consider style and period. Ideally, the frizzen should snap forward just as the flint reaches the bottom of the frizzen face or at about 30. The frizzen spring should have power in balance with the mainspring.

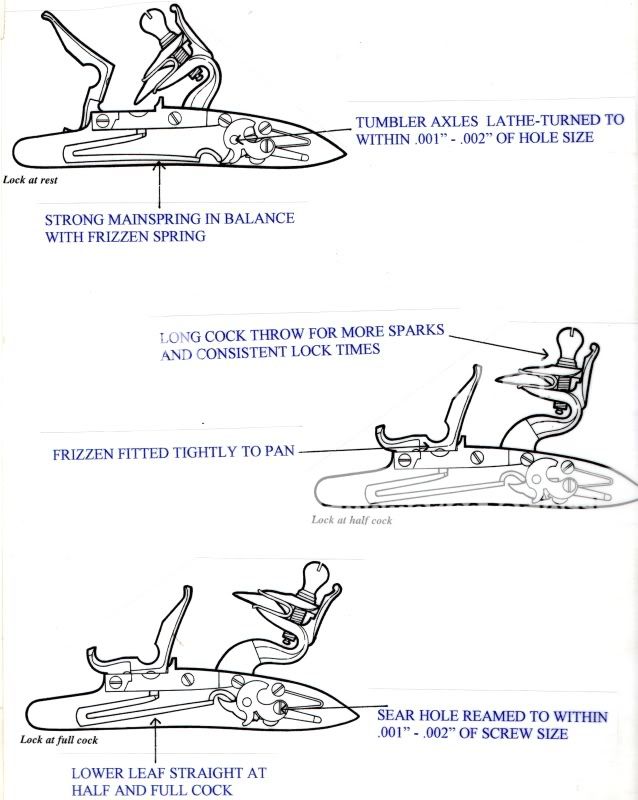

- 6. The cock should have a long arc of travel with half cock being located at more than Ύ of the arc. The inertia built up during this long travel enables the flint to quickly and consistently scrape the frizzen face for a large shower of sparks. A short arc of travel is fine on a percussion lock but undesirable on a flintlock.

- 7. Pan Cover The pan and pan cover should fit together tightly. A raised lip around the pan, which is recessed into the frizzen, is historically correct on some English and Continental locks, and adds a degree of waterproofing. A projection on the pan cover hanging down into the pan neither waterproofs nor is historically accurate. This arrangement simply obscures light and prevents one from seeing how closely the pan and pan cover fit together.

B.

Interior Geometry- 1. Mainspring First and foremost, the mainspring should have plenty of power. Power in the spring equals speed, consistency, and an abundance of sparks for sure ignition. There should be minimal space between the upper and lower leaf. The lower leaf should have a fair amount of curve when at rest. As the cock moves from rest to half and full cock the lower leaf should be straight. The spring hook at rest should be at the tip of the tumbler foot and should move up very close to the tumblers large shaft when the lock is at half cock. The tumbler should simply turn under the hook nose from half to full cock.

- 2. Tumbler The optimum curve of the tumbler foot is this:

This specific shape maximizes the power of the mainspring from rest to half cock and reduces the cocking force from half to full cock.

There should be a .005 to .010 bearing surface around both axles to keep the tumbler body from rubbing the plate and bridle. The cock notches should be concentric with the center of rotation so that the sear bar will be at the same position at rest, at half, and at full cock. - 3. Sear The sear pivot screw is set close to the midline of the plate on early locks, lower on late period locks. The sear nose should be smooth, square, and parallel to the tumbler notches. A bearing surface around the pivot hole is desirable.

- 4. Sear Spring Should be fairly heavy and should bear near the sear pivot for a light, crisp pull. Some curve in the lower leaf is desirable.

- 5. Fly The only function of the fly is to keep the sear nose from falling into the halfcock notch. It is necessary in a lock only if set triggers are used.

C.

Fit and Precision This is a must to prevent binding and wasted power, to increase speed and reliability, and for even, long wear and lock life.

- 1. All bearing holes should be drilled undersize and then reamed to specific diameters.

- 2. The frizzen pivot screw hole should be reamed to within .001 of the screw size and perpendicular to the plate and pan bridle. This will prevent binding and assure a tight pan cover to pan fit.

- 3. The sear pivot hole, likewise, should be reamed to within .001 of the screw size. An oversized hole will result in a heavy trigger pull with much creep as the trigger takes up the slack between the pivot hole and the screw.

- 4. The tumbler axles must be lathe-turned for roundness, smoothness, and for a tight fit in the plate and bridle holes. Both axles should be within .001 (+/- .0005) of the respective holes. A loose fit here (.004 or larger) will result in power robbing wobble as the hammer falls. A rough, undersized, out of round shaft turning in a hole will accelerate wear.

D.

Polishing Reduces friction of moving parts.

- 1. The interior of the lockplate should be polished to a 400 to 600 grit.

- 2. All moving parts (tumbler, sear, frizzen foot, frizzen spring, mainspring) should be polished to reduce friction, to increase speed and to improve consistency.

E.

Heat Treating Most manufacturers now supply springs that are ready to use. No further heat-treating is necessary. The frizzen and internal parts should be hardened and tempered according to the manufacturer's directions.

F.

Conclusion The function of a lock is to ignite the main powder charge. Some locks do this very quickly and consistently. Others do not. Good locks have several things in common: good design and geometry, quality materials throughout, and precision assembly. Most locks will ignite the charge most of the time, but only a precision lock will fire the gun reliably and consistently from shot to shot under all conditions. A quick lock is certainly desirable, but, if accuracy is your goal, consistency from shot to shot means more than speed. Precision equals consistency. Consistency equals accuracy.