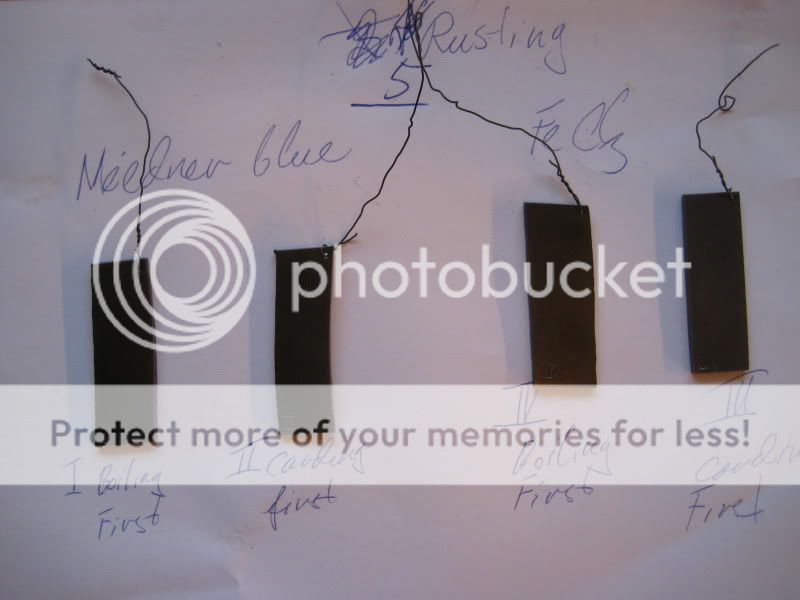

I did a pile of tests on different home brewed rusting solutions. The test were done on pieces of hot rolled mild steel polished to 320 and 400 grit.

Regarding to polishing :There was no difference regarding to rusting action and color on 320 and 400 grit. But 400 grit gave a smoother surface.

Rusting solution:The two best solutions were Niedner blue and ferric chloride. Applied directly on steel these solutions gave far to aggressive pitting and uneven rusting , but work great when diluted with 96% alcohol. Both gave nice dark finishes. The nieder blue gave a smoother surface than ferric chloride. Ferric chloride did not effect silver. Niedner blue turned silver an ugly brown color. Its the nitric acid/iron part that does this.

Niedner blue base solution.20ml cons. nitric acid + 17ml cons.HCl + 8grams iron + 260ml dist.water.

To make rusting solution, dilute base with 50/50 alcohol.

Ferric Cloride rusting solution.Add iron to cons.Hcl until it stops reacting. Filter through a coffee filter. This gave a clear yellow solution. Take 25 ml of this and add 125ml alcohol and 100ml dest.water.

Rusting, humidity,temp,timeRusting was done in a large plastic bucket with a tight lid. Large sponge functioned as water reservoir. The bucket was kept in the washroom. The tests gave best results at 28

0C and 90 minutes rusting. No visible rust at 18

0C and 24 hours rusting.

Carding and boiling.

Carding and boiling.Carding was done with gorbet steel carding brush. It made no difference if I carded first ,then boiled or if I boiled first and carded afterwords. Tap water and distilled water gave the same results(we have soft water). What mattered was boiling time. The pieces had to be boiled 1 hour to convert all the rust to black rust. I took a test piece, did one round of rusting,carding and 30 minutes boiling. Then I sanded off the color with 400 grit and boiled for 10 minutes and it blackend again. By repeating this, I found that one hour boiling is required to turn all the rust black.

Rusting and steel types

Rusting and steel typesFerric chloride gave poor results on caseharden screws. Neidner work better but needed eighth applications. The GM pistol barrel was alot easier to rust blue than the test pieces of mild steel. This is the barrel after two rounds of rusting with the ferric chloride rusting solution. The test piece next to it was rusted 8 times.

Best regards

Rolfkt