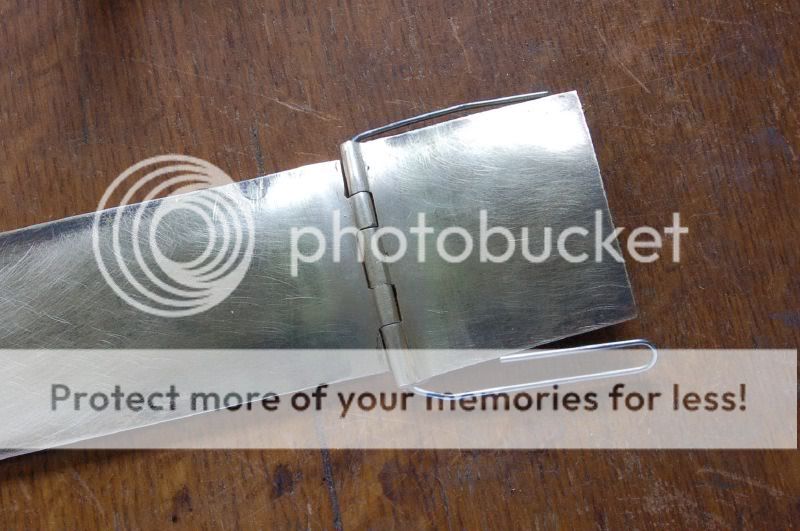

Hinge forming block, thanks to Mark Elliott's idea. I think Mark had a tutorial on hinge forming on the old ALR. Anyway, I made up one of these for getting that nicely formed hinge barrel. The block has a a round top tab, about .08. The hole closes down as you work the hinge, it works down to about a 1/16" pin hole.

Making the sharp inside corner. anneal after this step. Use a nice sharp cornered block to form on. The vise jaws are a little too messy to get a good clean bend over.

Formed corner and forming block. Anytime you make a sharp bend like this, anneal the brass afterwards. If you don't anneal, the brass can crack at the next bend. To Anneal: heat the brass to dull red and dunk in water. It will be dead soft again.

forming block and hinge piece clamped up with the corner of the brass tight against the forming block.

gradually pry the tab up with a chisel, until you get the tab up high enough where you can use the hammer to start wrapping the brass around the nosing of the forming block.

Hinge tab bent up and over the nosing bead of the block

Partially formed barrel. Anneal when this step is complete. Now scrub both inside faces clean, as they will be soldered after the last step.

Hold wire in groove with a turnscrew while tapping tab over with a hammer.

peen tab over until snug. A hardened music wire pin is necessary, or you will have trouble pulling the pin after you're done forming. Pull the wire, and hard solder the seam.

I missed a few pictures along the way, but this is the end result. .06 brass, curved finial and door. Seam is tight when shut; when the door opens, so does the seam.

I formed the barrels over .062 wire, but the pin now is about .04. When I fit the knuckles, I reamed it out to .062 wire size.

Soldered folded over and doubled hinge area. The hinge knuckles have to be in a pretty straight line for the hinge to be able to open. If the hinge has too much curve, and the pin is snug in the barrels, the HINGE AIN'T GONNA OPEN.