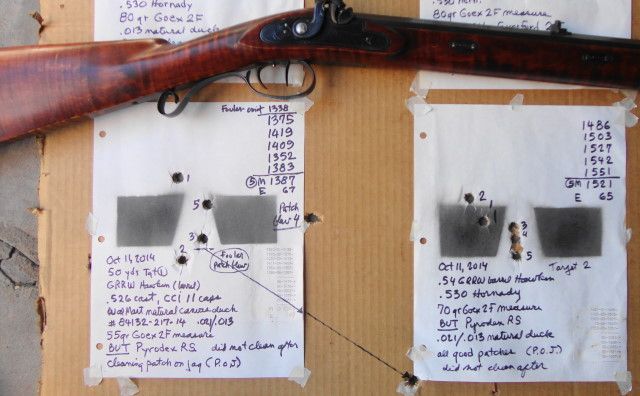

I just gave my favorite .54 Hawken to my nephew David, after testing some patching. He should get the rifle in the mail October 15. See "Chronographed Loads in my Custom Engraved .54 Hawken" on October 09, a few posts below. He has no experience with muzzleloaders and could use a good mentor around Prairie du Chien, WI or northeast (McGregor) Iowa. If anyone can help, please E-mail me. I gave him my "operator's manual" and tested load recipes, but now realize he may not have real black powder in time for the Iowa general gun deer season. I think the muzzleloader season was this past weekend. So I tested Pyrodex RS in another ML I built and will be giving to another nephew and will send David this report.

This next rifle shown above was a parts set special from Track of the Wolf, the main thing was the nice wood in the inletted stock. I put a different barrel in it, a Green River Rifle Works .54 1" x 36". A gunsmith friend had used this barrel as a Hawken then took it apart and traded the barrel to me towards a .40 Issac Haines flinter I built. I intended to cut the barrel to 32", but he said not to for the bore had choke (a slight constriction near the muzzle) which made it the most accurate barrel he had used. With a tight patch and feeling how it pushed through the bore, I determined that after the first 2 1/2" from the muzzle there was a reduction in bore size for about six inches, then the bore loosened up slightly to the breech. So I hack-sawed it off at 32" and had a choke-bored barrel, which is supposed to improve accuracy.

In GRRW's catalog from 1978 when I built a Leman in their shop, they said: "P.S.- PLEASE don't cut the muzzle off our barrels if you want to shorten it. If you do, you will cut off the choke and lose accuracy thereby. Always shorten the barrel from the breech. May you be forever haunted by the devilish spirit of lost accuracy if you shorten from the muzzle."

My friend Neill Fields built barrels at GRRW to start, then rifles. He said the "choke" was an artifact of how the bores were rifled and that he personally cuts off the muzzle end with no concern for loss of accuracy. I have cut off six or eight myself. So that is the barrel, the rifle is Track's Hawken set of parts. Back to testing.

I sent David a half yard of the red canvas duck I just got from WalMart, but it is thinner than the previous piece I got from them and tested, which worked well. This miked .018/.011 (crush), only a thousandth or two thinner, but looked a little looser woven. I tested it in this rifle but also some natural canvas duck I got at the same time, which was thicker and tighter, .021/.013, UPC# 84132 217 14. I cut it into 1 1/2" squares and did not wash it.

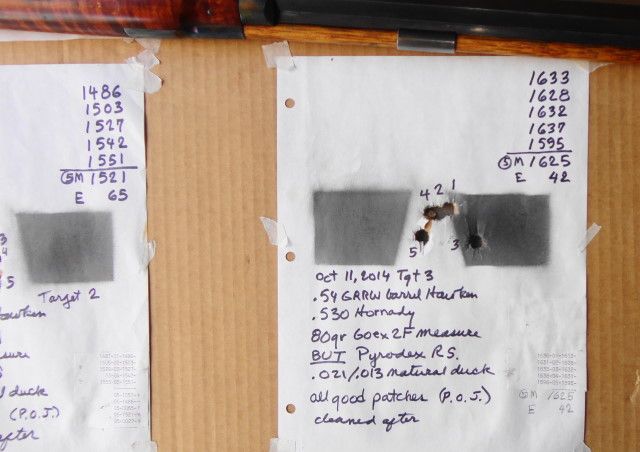

Pyrodex or Triple 7 powders are loaded by bulk equal to a measured black powder charge. I started with a brass cartridge case that holds 55 grains by weight of Goex 2F and used that bulk volume of Pyrodex RS. This thinner red duck blew two patches with .526 balls, the last I had. Five shots averaged 1387 fps with poor accuracy (bottom left target). I seated each ball with a patch damp with the lube (half Murphy Oil Soap and half 91% alcohol) on the seater jag, so wiped the bore down to the seated ball at each shot. I did not wipe the bore after this target. I next used the .013 natural duck (much easier to find red fired patches on the ground) and 70 grains of Goex 2F bulk measure of RS with .530 Hornady balls. After two "bore seasoning" shots, it grouped well at 1521 fps. (You will note on these targets that the first shot is usually not in the group, which is why I often fire one or two "bore seasoning" shots before the main group). I shot them all for record here. All patches were good. Again I did not clean the bore after this group but went to 80 grains Goex 2F (weight-corrected) measure of RS. All patches were good, it grouped well at 1625 fps.

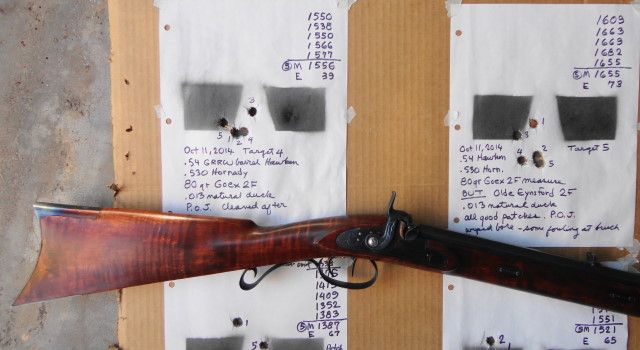

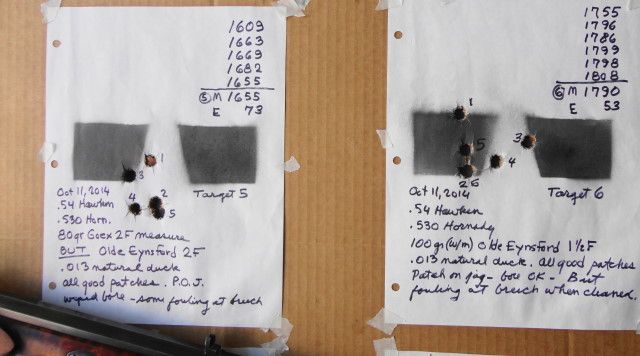

I cleaned the bore out with Murphy Oil Soap, rubbing alcohol and hydrogen peroxide mix, dried it, and then went to 80 grains of Goex 2F on the top left target, using the same measure. That was a good group at 1556 fps, all good patches. Cleaned the bore after the group and used that measure to hold about 80 grains of Olde Eynsford 2F on the middle target. A good group (first shot out), 100 fps faster at 1655 fps. There was some fouling at the breech when I cleaned after this group but I did not feel fouling as I seated each ball.

Next on the top right I shot 100 grains (weight-calibrated) of measured Olde Eynsford 1 1/2F, a very good load in .54 rifles. Because the first shot was out (not called out), I shot five more, velocity of six was 1790 fps. With the damp cleaning patch on the seating jag, as for all shots today, the balls loaded with no feel of fouling. But when I cleaned the bore after the 1 1/2F, it was "gritty" at the breech end.

So now I have Pyrodex loading information (70 to 80 grains bulk equivalent of Goex 2F, and a 7mm Remington Magnum fired case holds 76 grains of Goex 2F) I can furnish David and with this rifle, which I will soon be giving away, until they get Goex, perhaps at the Prairie Rendezvous next June. And a better patch material, the natural duck canvas from WalMart. It is a good material that can handle Pyrodex and Olde Eynsford. But they can hunt deer this fall if they want.

I like this barrel, but I do not know if the choke made any difference. Look how frequently it throws two or three balls into the same hole at 50 yards, and that with four different powders. I think the Hornady balls grouped tighter than the ones I cast, but maybe it was this barrel. I could not tell any difference in feeling the ball pushed down the bore. I'll have to shoot it some more.