I have gotten some 1,2mm (0.047") 24k gold wire that I'm going to use for weddingbands on the pair of pistols I'm making.¨

I wanted the bands to be 1,5mm wide(0.059"). How deep should the wire channel be? I made a test block where all the channels were machined 1,5mm wide with these depths: 0.4mm (0.016"), 0.5(0.020"), 0.6mm(0.024") and 0.7mm(0.0276").

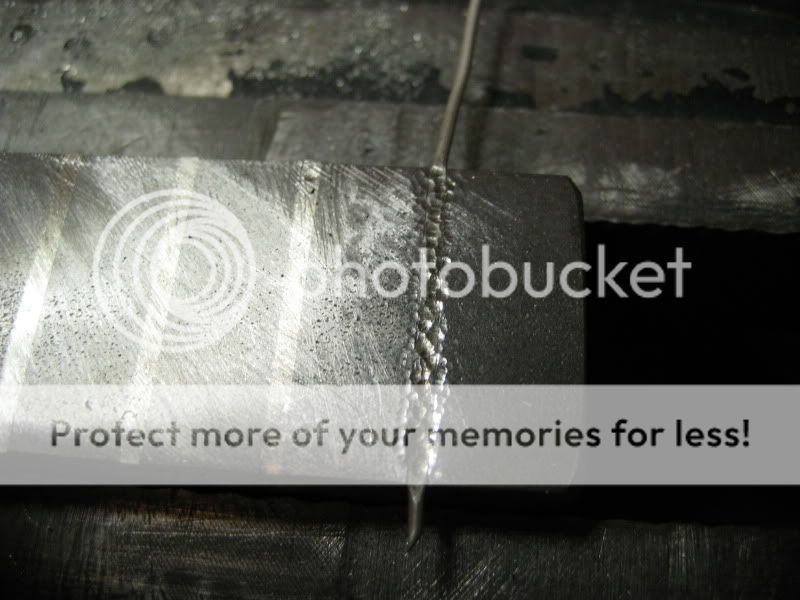

The channels were undercut with a chisel and barbs raised. I used pure silver wire for the tests. It has about the same mechanical properties and gold is to expensive to experiment with.

1.2 mm wire filled the 0.4mm , 0.5mm and 0.6mm channel, but was to small for the 0.7mm channel. The channel to the left is 0.4mm. The channel to the Right is 0.7mm

The channels where undercut , holding the chisel at a 60

oangel. As you can see this angel was not steep enough for the 0.4mm and 0.5mm channel . Undercutting messed up the channel edges. When undercutting an inlay this shallow, the chisel needs to be held at at steeper angel, about 75

o. On this picture the channel to the Rigth is 0.4mm.

I Was able to fill the 0.7mm channel by by using a small punch and forcing the silver to spread out and fill the channel. This left the silver wire abit below the iron surface. But it was easy to flush file it. I'll be tring for a channel depth between 0.5 and 0.6mm.

Best regards

Rolfkt