Guys,

The question was what kind of tool would have been used originally for countersinking screws. So, lets try to back off away from the Bridgeport and get back into the 18th c.

There are three styles of countersinks; for a brace, for a bow drill, and for a hand held tool. These are scans from the mid 18th c Wyke tool catalog. None of these chatter when used by hand, they probably all chatter when attached to an electric motor.

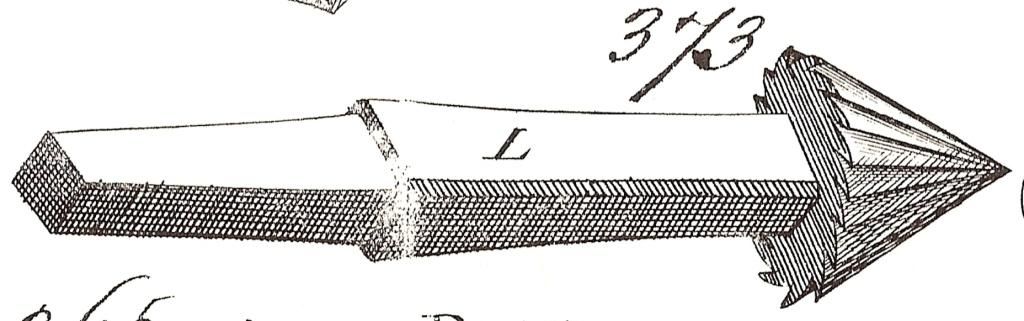

The countersink for use with the brace, for use in wood only

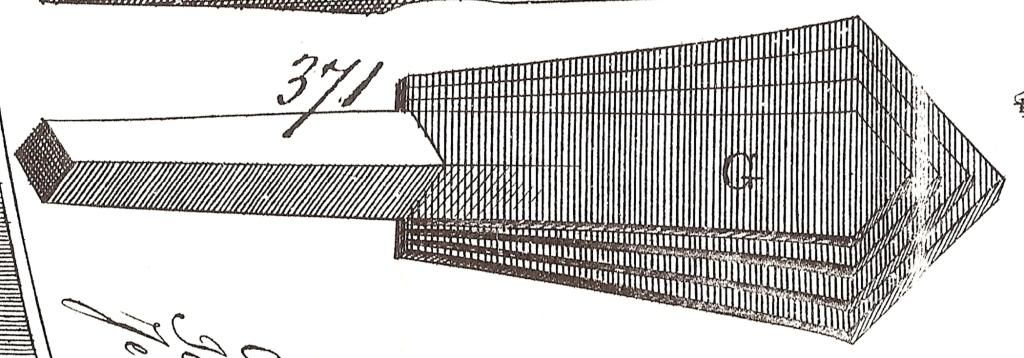

The countersink for use with the brace, for use in metal, like a very large drill bit

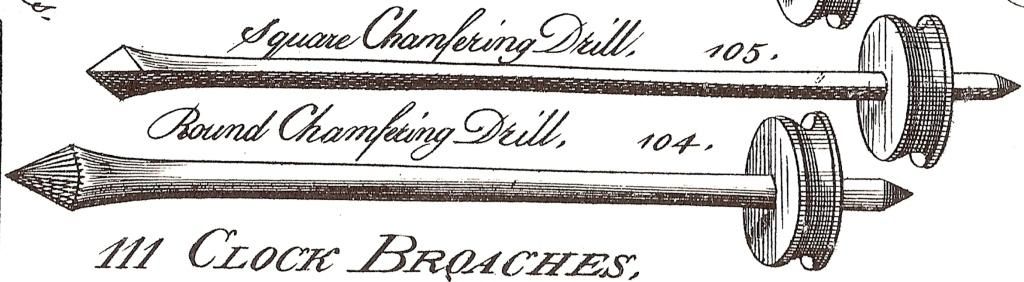

The countersink for use with the bow drill, for use in metal

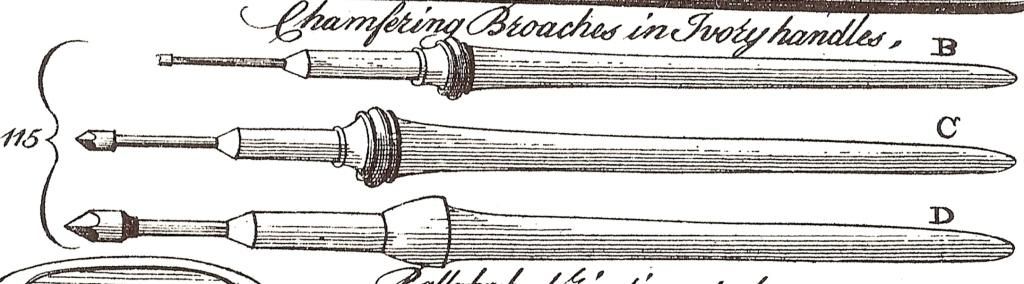

The countersink for use hand held, for use in metal and only for very tiny screws - probably not used by a gunsmith

I do have some original examples if you guys would like to see them

Jim