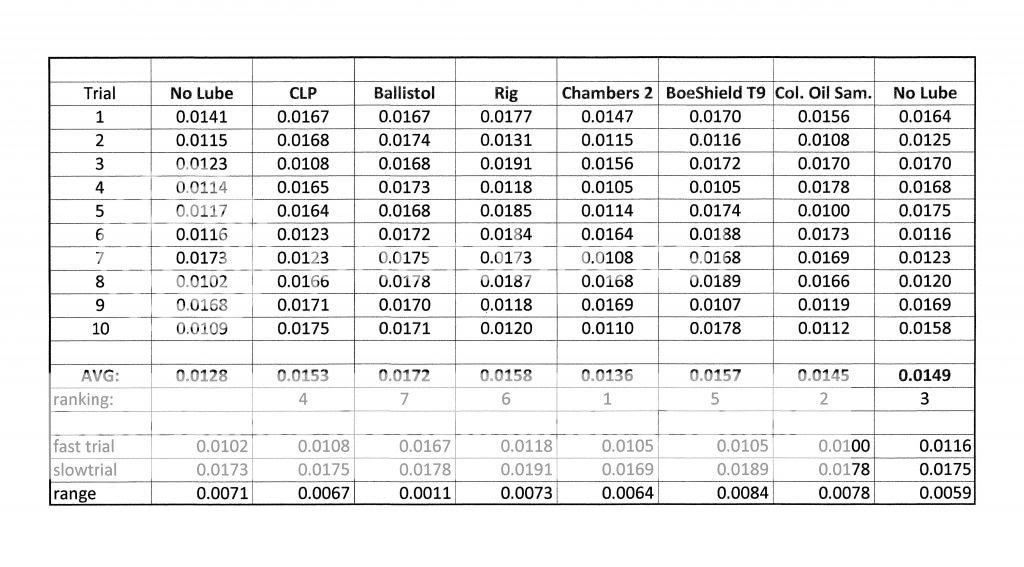

Here are a few photos of the setup and the spreadsheet that includes all the trials:

The trials are in the order of testing left to right. The "no lube" in the left column is the one in which I felt I did not clean well enough to use. Instead I decided to retest at the end. That trial is on the far right. The times within each trial are in order from top to bottom. This is probably not as significant as it would be if a flint edge was used. The range within each trial was wider than I expected. The exception is in the Ballistol group where the range is significantly smaller than the rest. It was the slowest in the group also.

This is the overall setup I'm using.

This pic shows the fixture with the Siler installed. The orange RCA plug in the forground holds the led emiter, while in the background is the detector (black). The infrared beam is positioned right above the frizzen. When the frizzen rises, the beam is broken.

This shows the fixture from the back. Now the detector is in the forground. Here you can see the plunger below the sear with a thin brass blade between. When the plunger pushes the brass against the sear, the contact is made that starts time.

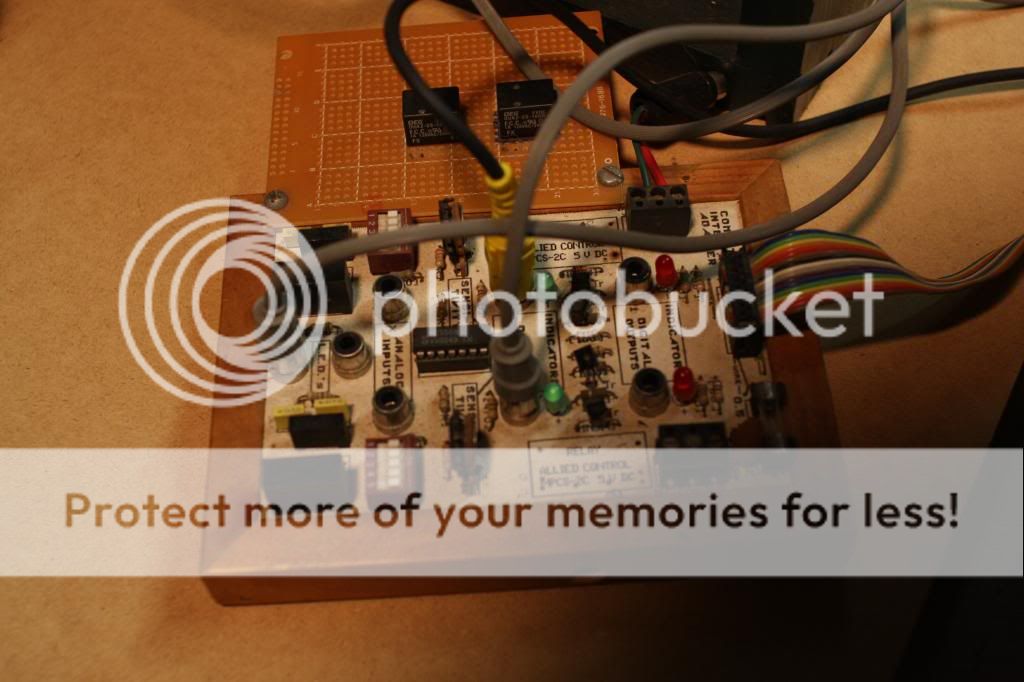

This last pic is the interface. The glowing green led lets me know that the infrared beam is not broken.

The mention of ultrasonic cleaning sounds interesting. Using brake parts cleaner sounds good too. Would the parts cleaner leave a coating that could be removed by alcohol? BTW, I figured alcohol would leave no coating. Hope that's right. I should mention that I would use compressed air on the lock until no alcohol was left. I was surprised to see alcohol coming out of the sear and sear spring screws on the front of the lock plate.

Regards,

Pletch