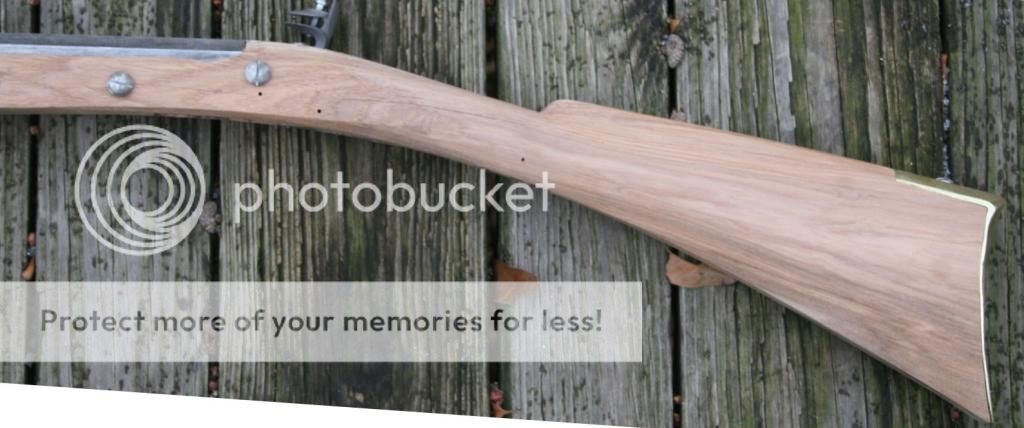

I'm working on a rifle based largely on this smooth rifle stocked in hickory. Call it a Lehigh; I call it a Bucks County rifle because the guard is the same as a Verner. The original is a smoothbore about .60 caliber. I wanted a squirrel rifle so went with a .36.

I started with a crooked piece of hickory, part heartwood, part sapwood, some mineral streak, only 1.75" wide. There wasn't a single true plane on the plank and it wasn't very deep. Luckily the original has no cheekpiece. I was able to put in 1/4" of castoff.

Barrel: Rayl B weight, .36. Lock: Chambers late Ketland. Furniture: Reeves Goehring Verner.

I've got the barrel in, ramrod groove and hole, lock and trigger and guard and buttplate in. Buttstock mostly shaped.

I had trouble with the lock placement and the tail is lower than I'd like. On the original, the top of the stock at the breech is kind of flat- the lock is mounted higher and so the edge of the lock molding is sort of high. I thought I could "fix that". Mistake #1. Now it's hard to achieve the look of the original, that of a horizontally thin wrist. Live and learn. My first build in over 2 years, and thankfully it's for myself. Still, I want it to be all it can be, so any help is welcome, though the stage is a little late. These are snapshots- my main areas of concern are the top of the wrist, that it flows, and the nose of the comb, which I need to fix. I have the web as thin as I can get it near the breech and there's almost no wood underneath the 5/16" ramrod hole- the guard front extension inlet exposed the hole. So I think it will be thin as I can get it vertically with the lock where it is. Fore-arm then lock panels are next.