Guys,

Really great questions, I will do my best to give an answer. I think that the three rusty looking tools are blacksmith made, not made by a professional tool maker. They are fully functional, but rather crude with no embellishments. The clean tool with replaceable split dies seems to be made by a professional tool maker. Very similar to tools shown in the mid-18th century John Wyke tool catalog.

Such tools were not made from case hardened iron. The rather thin case hardened skin would be much too fragile for the heavy stress operation of swaging screw threads. But, it seems that the use of hardenable high carbon steel was limited to only the replaceable split die pieces, or to the section of the tool than would be in direct contact with the work piece during the swage operation. In this case there is a forge welded seam between the iron and the carbon steel.

Here is a magnified photo of the Colonial Williamsburg reproduction tool. You can see the slight difference in color between the two materials, about 1/2 inch on either side of the actual die section. The dark black line you see is just a slag string inclusion in the wrought iron, not a crack or flaw.

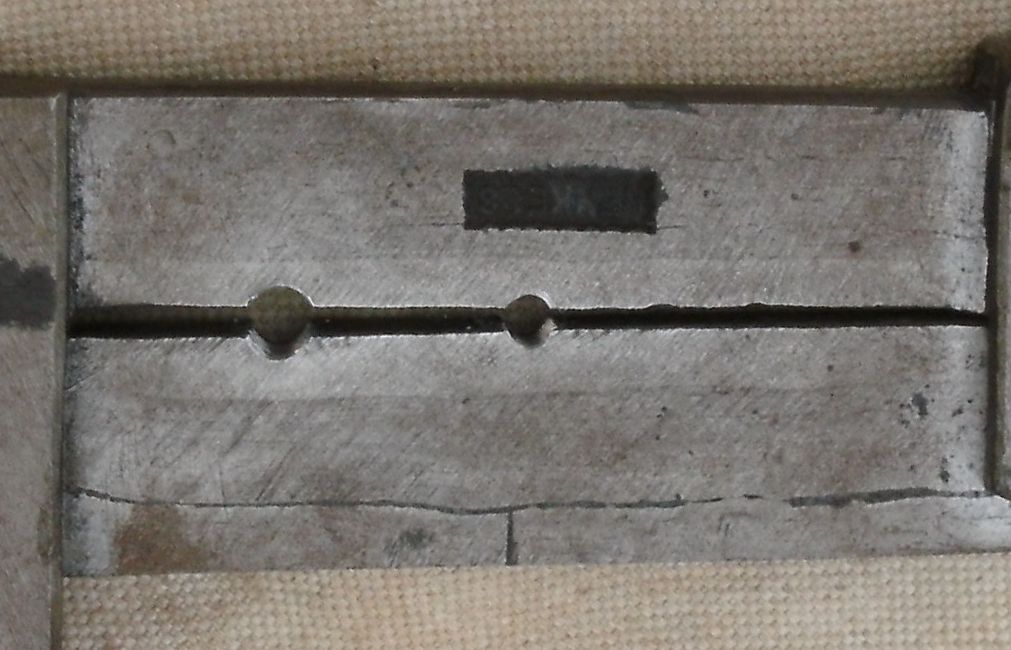

Here is a magnified photo of one of the original rusty tools. You can see the same interface here, but it is a bit more difficult to see due to the rust. A lot of original tools were made in such a fashion as carbon steel was so expensive.

The replaceable split die on the clean tool is all carbon steel while the rest of the tool is iron.

Jim