Guys,

Here is another How Did They Do That? This will show the tools and technique for threading the breech of a gun barrel using 18th C style tooling. This is a two step process, similar to what modern M/L gunsmiths use. The barrel is a forged wrought iron rifled barrel, 0.515 caliber.

First the breech end of the barrel is opened to the proper hole diameter and depth using a tool called a grinder. It only opens the existing breech bore hole a bit to the proper diameter for the threading. The grinder is used as it is one of the rare 18th C tools that would actually cut a controlled diameter hole. The "fish tail" drill bits and tapered reamers could not accomplish this task. Here is a photo of the grinder and tap set used.

The grinder is used with a hand brace to cut the hole as shown. The breech end of the barrel has a significant lead-in or funnel shape to help start the rifling cutter, it would be difficult to start the rifling cutter on a square edge hole. So as the grinder cuts deeper into the bore, it also begins to take a bigger cut as the grinder works its way through the funnel section.

The breech is cut to a depth of 0.53 inches.

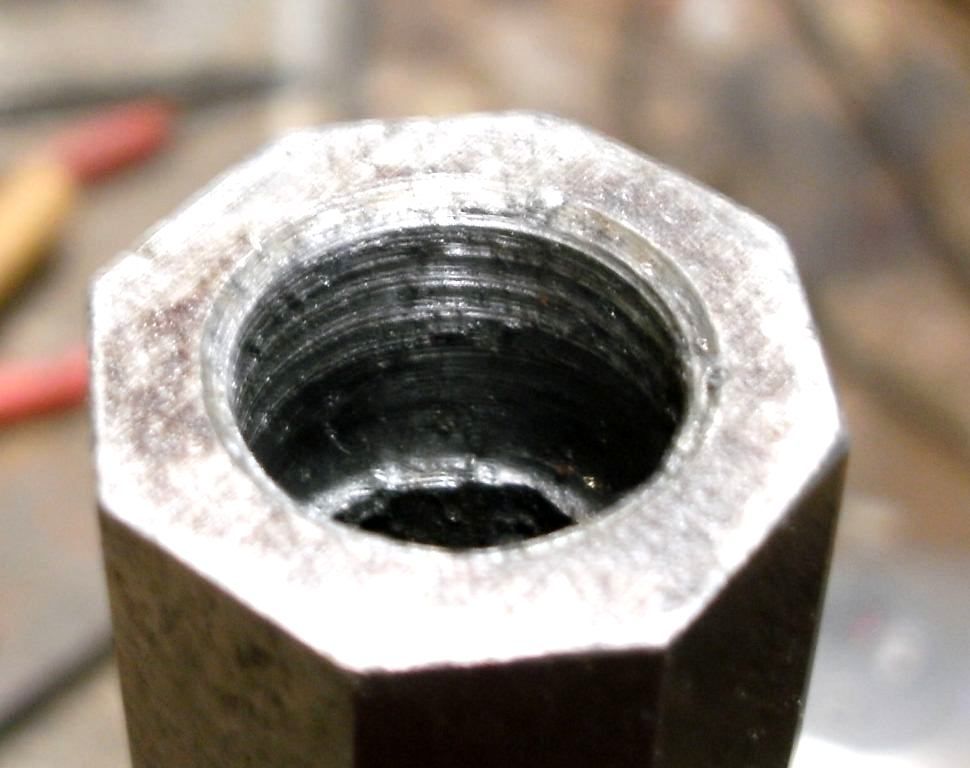

Here is what the resulting finished hole looks like, 0.53 depth and 0.58 diameter.

Now to form the threads. Here is a photo of an original 18th C set of breech plug taps alongside of the set I use.

The first tap has a long lead-in guide to keep it on center, it only forms about the first 4 or 5 threads. This is a very easy tool to use, the tool stays properly centered and it forms or swages the threads, it does not cut.

The tools are turned using an original tap wrench. The rectangular drive sections of the new set of taps were made to fit the old wrench.

Next the tapered tap and the bottom tap are used to finish the thread. Again, the threads are not cut, they are formed or swaged. The hole starts at 0.58 diameter and ends at 0.55 diameter as the threads are formed. The finished thread size is 0.614 diameter, 20 threads per inch.

This tooling may not work well on modern steel barrels as the steel we use today is significantly less ductile than wrought iron.

Jim