Guys,

Here is the rifle bench that I have used since the 1970's. The cam is ash wood about 3.5 inches diameter X 4 ft long. The cam has seven grooves X 1/56 twist. The grooves were laid out mathematically and cut with a chlsel. Really no short-cuts in making this thing. I cannot imagine making another just to get a different twist!

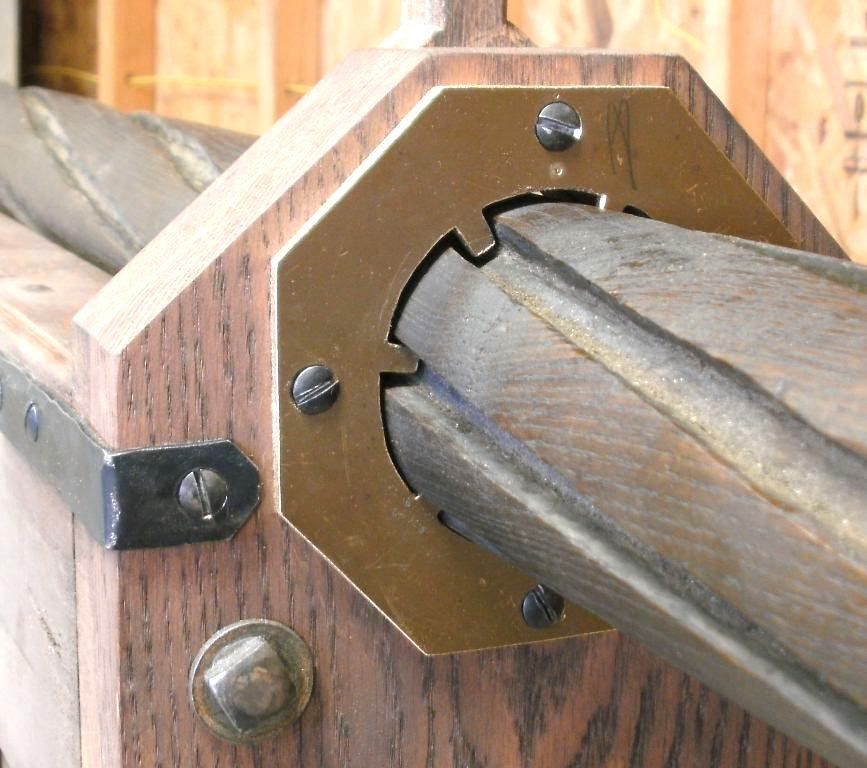

Here is a rifling machine from the mid-19th century used at Ligonier Pa by the Fry brothers. It uses a large caliber rifle barrel for the guide. The barrel/guide is rotated to move the cutter head from one groove to another. With this machine you still cannot change the twist, but you can change the number of grooves cut. With this machine you can cut 6 - 7 - 8 groove barrels.

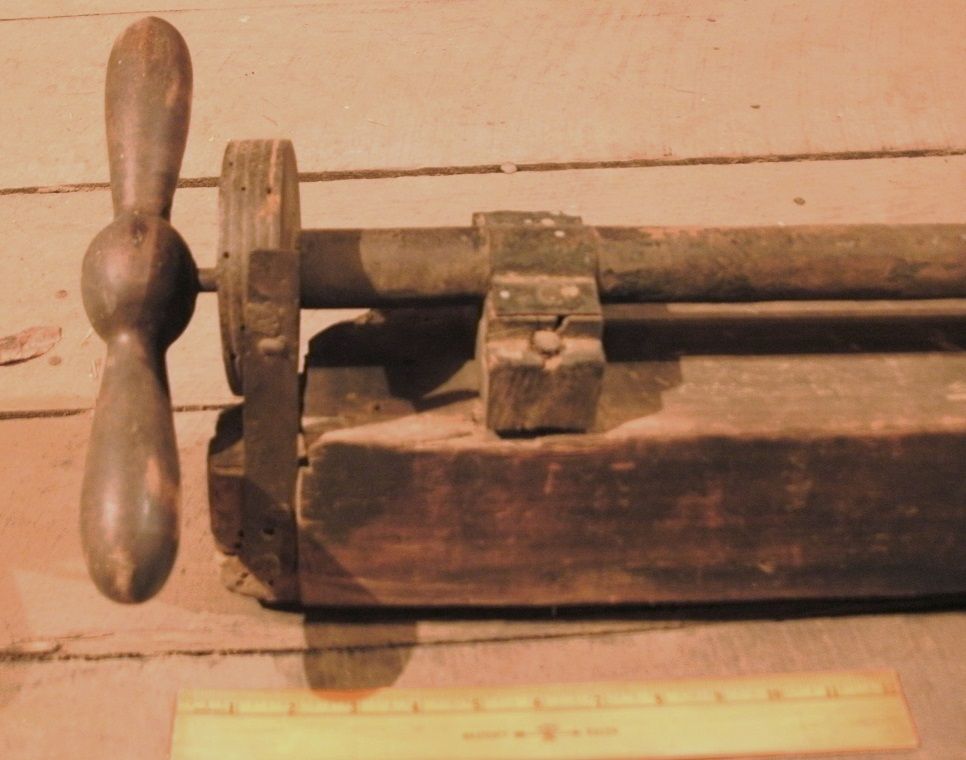

Here is a very similar tool that was used in Somerset County Pa in the 19th Century by the Border - Dunmeyer - Knupp gunsmiths

A rifling bench in the 19th century style surely would be a lot easier to make than the 18th Century style. Let me know if you wish more photos of these benches, or if you wish to inspect the actual tools.

Jim