Several members have ask about a short tutorial for making a TN trigger and I said as soon as I had enough pics I would do one. I don't have every single step in the tutorial. I'll add to it as I have more pics. This is not the only way to build a trigger. There's a lot to building a trigger from scratch and even more when you consider the differnt spring arrangements and trigger configurations.

I hope with my pictures, a store bought trigger, and Mr. Webbs new book you'll be able to make a proper TN trigger that will make and serve you proud. If you only need one, then modifying a store trigger will get you visually there. Before I start, special thanks to Steve Bookout who spend considerable time teaching me the finner points of trigger building.

Building a single phase, double set trigger.

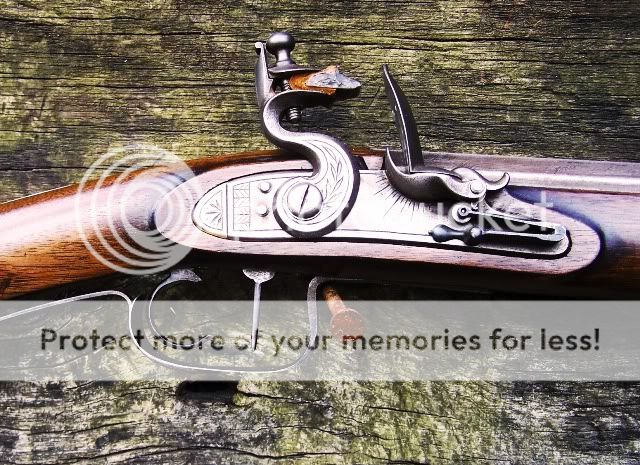

To build a proper trigger for a TN rifle you must first know why you need to. I hate to admite it but went a long time before realizing there is a difference. Double trigger is a double trigger right? If you look closely at Southern guns you will see lots of different style set triggers. I'm going to build a set appropriate for a upper E. TN rifle.

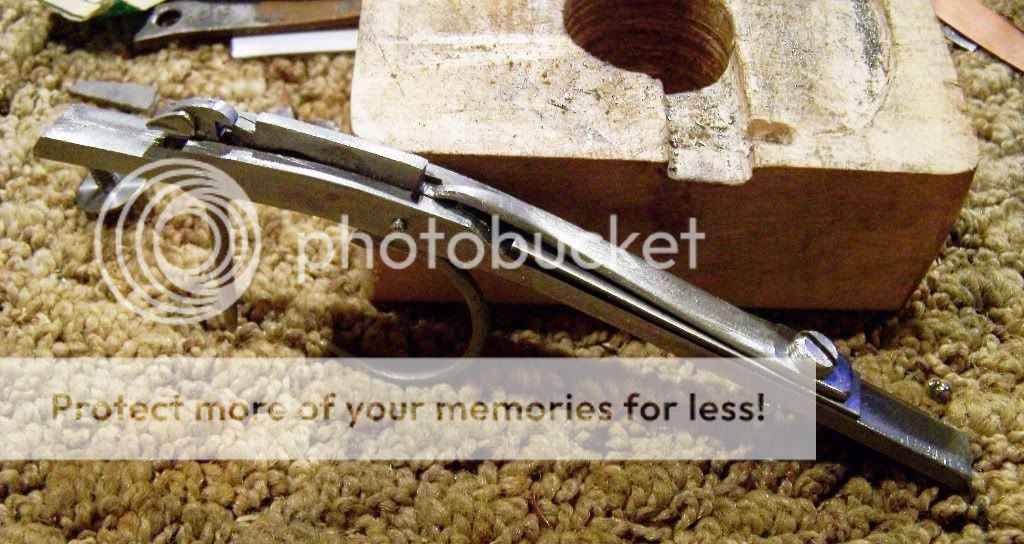

Here is a standard store bought double trigger.

Here's an original TN trigger.

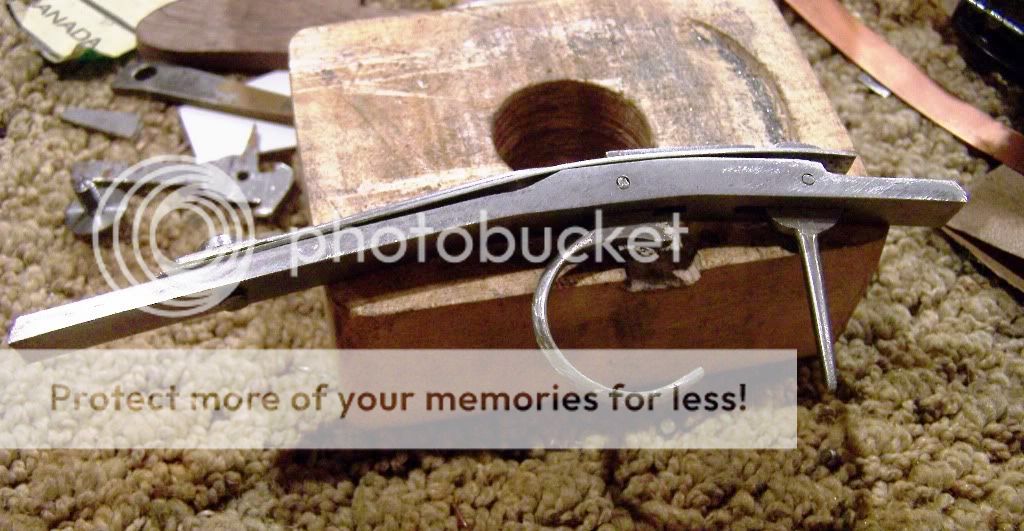

Here's one of my hand made triggers. Closer to an original?

Ok, where to start? Your best and easiest route is to buy a store bought trigger to use as a pattern to get the basic size and deminsions. Chambers sells a very good start. A single phase double trigger made by Bud Siler. Draw the parts out. Make the modifications to make it look like a TN trigger and go to town with your hacksaw and files.

You will notice the rear trigger is drawn out with the curve straight. There's a reason for that. You need to turn it on end before you cut it out and beat a flange on the metal so it ends up being widder than the piece of metal you are using.

Now you can proceed with cutting it out with a hacksaw and rough shaping them with a file.

Now to bend the rear trigger. I use a vice and round piece of pipe to get a nice round curve.

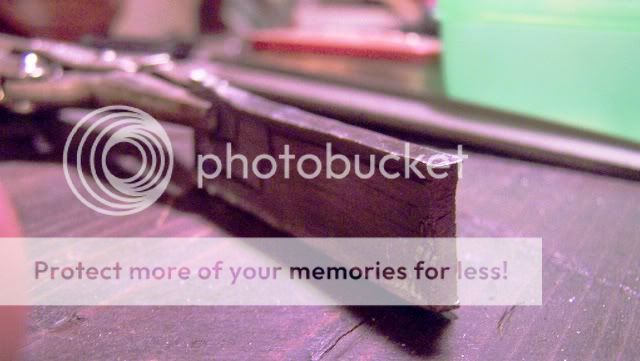

Now the part I hate. There are many ways to accomplish this. I'll show how I started out doing it which is the hardest but requires the least amount of special tools. Get yourself a piece of mild steel. Crank her down in the vice and start hack sawing grooves about 1/2 the thinkness on the front and rear of the trigger plate just like you were doing a dovetail in a barrel. Yes, it is a pain and labor to do it this way. MUCH easier to put in the forge and shape with a hammer. I'm sure easier to grind off and for sure easier to mill off. The absolute easiest way........Use the trigger plate from the triggers you bought to use as a pattern so it doesn't go to waste.

Punch a set of holes and drill out for the triggers to go through. Use a small file to connect the dot and progress with a larger file till you get everything to the right size.

Flip thr plate over and cut a slot right down the middle.

Now you are ready to fit it all together. Well, you have to make the main spring also but that's pretty straight forward and by now you may have decided to use the store bought one.

A little tweeking and you should be done.