Guys,

Here is a way to re-use an old damscus/twist iron barrel without a lot of cost. It starts with an old 12 Ga. twist iron barrel, from E-Bay for only $15.

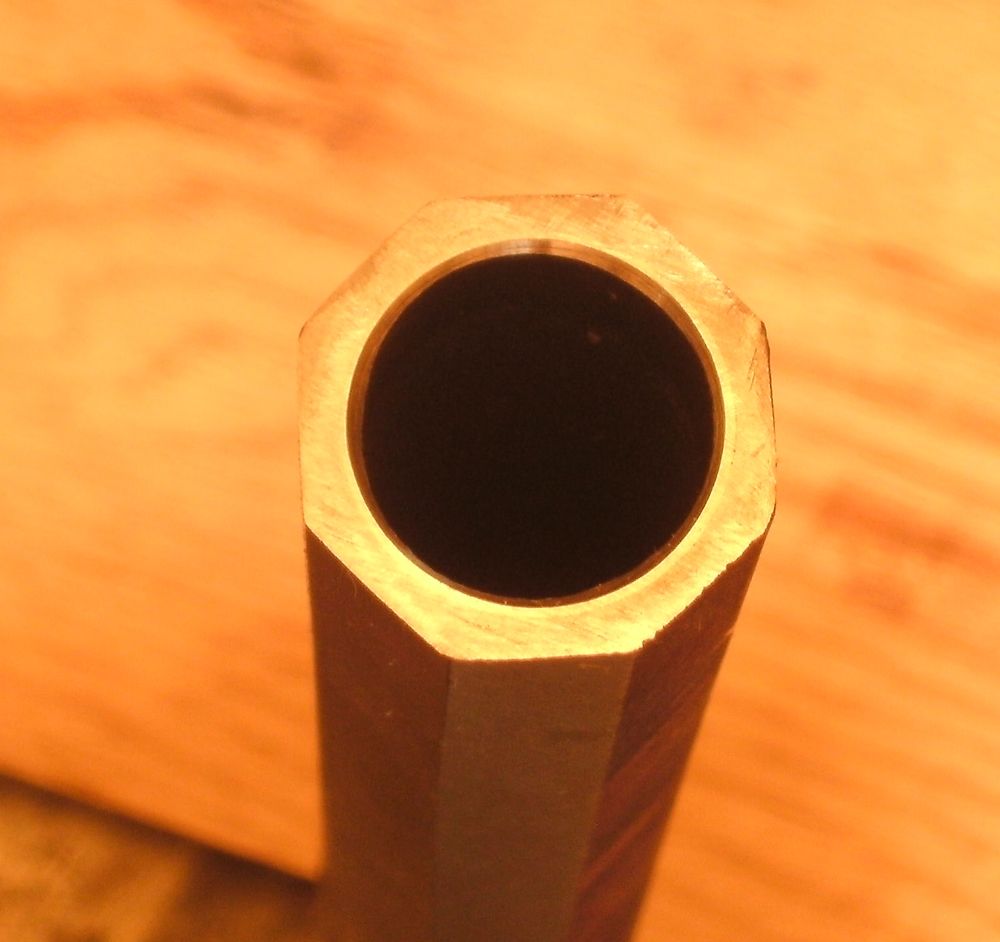

I cut the barrel at the end of the forcing cone, then two 12 inch sections. Since the barrel has a significant taper, I will make the heaver section an octagon pistol barrel and the thinner section a round barrel. Here in the heavier section along with a liner tube.

The bore of the original barrel is 0.726, so I turned a piece of 3/4 inch tube to an O.D. of 0.723, leaving one end tapered out to the full 3/4 inch, sort of trumpet shaped.

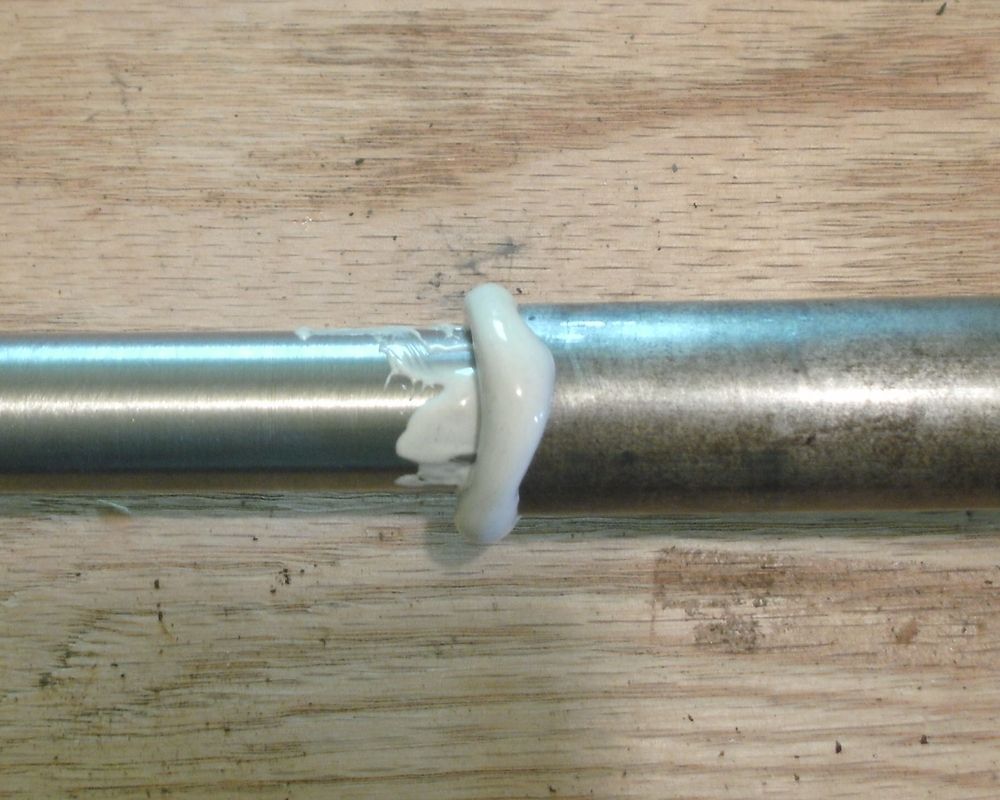

I plug one end of the tube with a wood cork and insert the tube liner with a lot of slow set epoxy. The photo shows the excess rim of epoxy as the liner is inserted. Likewise, there is a large wad of epoxy being pushed through the bore - a messy job.

Here is the breech end after the liner insertion, you can see a bit of the wood plug.

Here is the muzzle end after the liner insertion the trumpet shaped section has been pushed into complete contact with the original bore, no gap.

Breech end with a liner, you can see the gap on this end. There is no gap at the muzzle end.

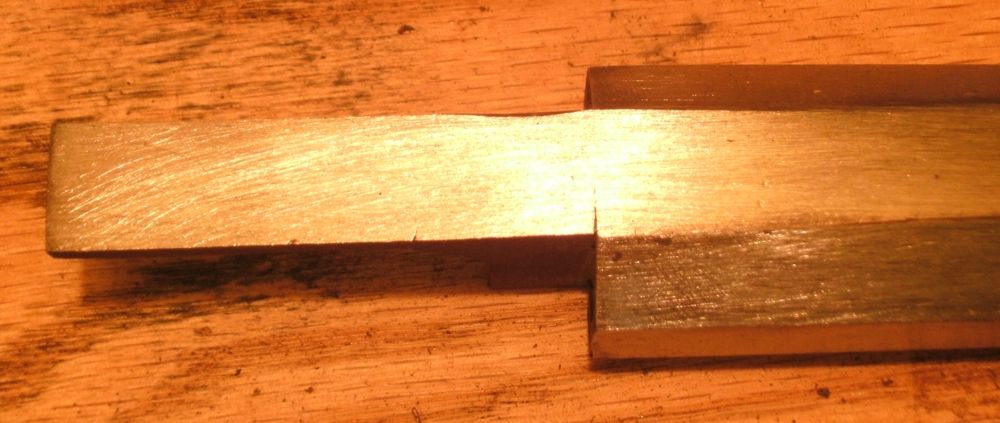

I want the breechplug tang to show the twist pattern so I cut two slices of the cut-off chamber end to be the tangs.

I forge the slices out flat, but remember which is the original outside surface, so the final surface twist angles will match.

I Install a modern breech plug, 7/8 threads and then weld on the twist iron tang, remembering to keep the outside surface out.

Where the tang ends up, I file/grind the 8 barrel flats to correspond.

Here is the finished muzzle end. I forgot to tell that the liner is stainless steel, so I chamfer the muzzle just to the interface so it is not too obvious.

For the thinner round section I will use an old 0.54 T.C. Hawkin rifle barrel for the liner. The bore condition is only so - so, not perfect, but OK. Again I turn the outside to 0.723 with a trumpet shaped flair at one end. Installation is the same as above. But here I simply soldered the twist iron tang to the existing breech plug tang. Bend the tang before soldering because bending the tang after will probably damage the solder joint.

Here is the muzzle end after the rifled liner installation, no gap.

Here is the round barrel after a simple acid etch with muriatic acid, showing the pattern.

Barrel dimensions:

Octagon - 12.06" long, 1.10" flats breech, 0.89" flats muzzle, 0.664 bore, smooth

Round - 12.06" long, 0.94" breech, 0.84" muzzle, 0.54 bore, rifled

Jim