From what I understand, original longrifle ramrod tips are made of rolled thin sheet steel, tapered, with a brazed seam, and some brazing down in the tip to provide enough extra material to be able to thread it.

I've made a couple but man, it is hard work. Maybe the steel stock I am using is too thick. Then I have the problem of the tip either being super tapered so I can thread it directly to 8-32, or too wide and it's hard to get brazing in there to fill it, then drill it, etc.

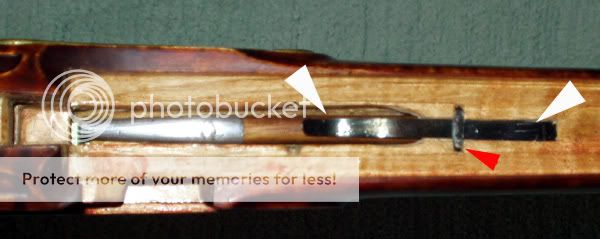

Here's an example that kind of worked. Ignore the spoon spring that holds the rammer down and in place.

If you guys make your ramrod tips how do you do it? On an early rifle with a tapered ramrod and everything else sort of "period" I feel obliged to make the ramrod tip like originals.