Guys,

HDTDT = How Did They Do That? These tools are from the gunshop of the Fry family of gunsmiths, Ligonier, Westmoreland County, Pennsylvania, and are mid 19th c. There is about 100 - 150 freshening rods shown in the box, mostly for rifle barrels. Freshening was the process used to recut the entire interior surface of the barrel. I believe that this was done frequently, perhaps every year. I surmise that each freshening would enlarge the bore by a few thousanths of an inch. So, over the active life of a rifle barrel, many generations, the caliber would increase by a significant measure.

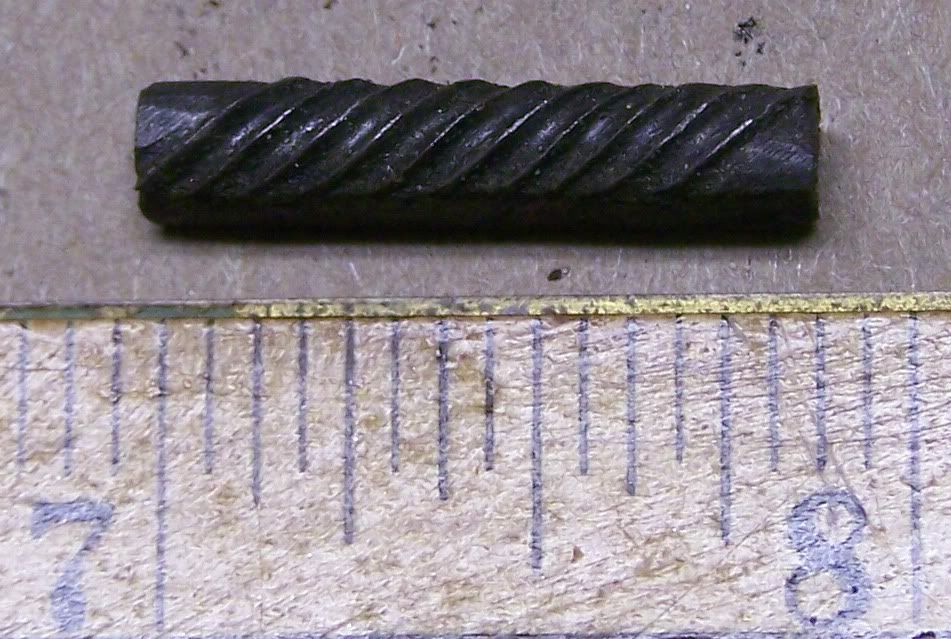

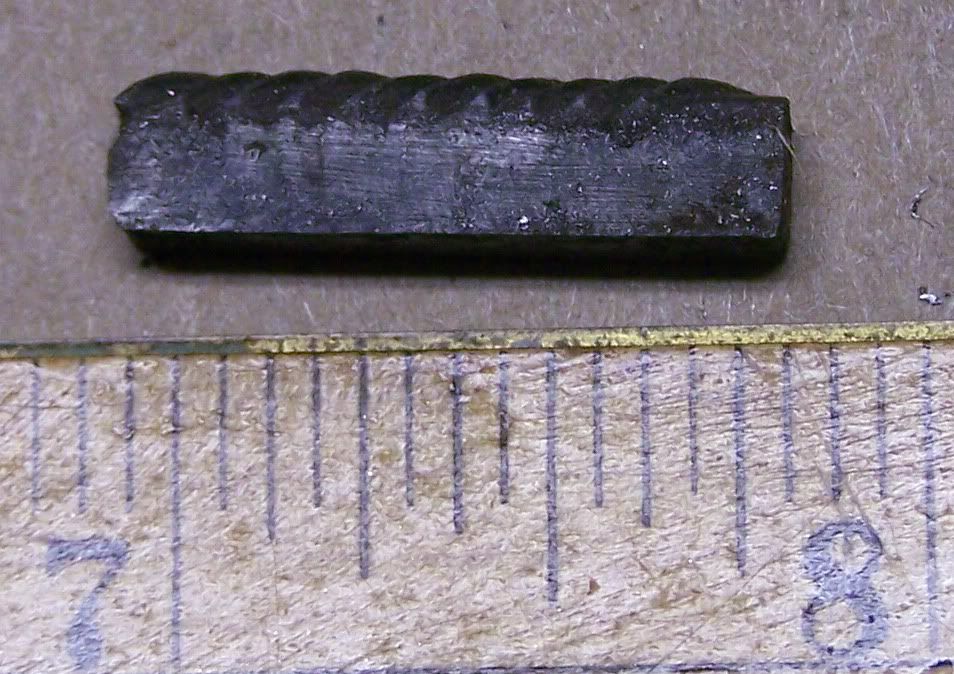

The individual rods have a wood shaft and a cast lead body showing the barrel rifling grooves. Cutters were inlet into the lead, one to recut the barrel lands, and a second to cut the barrel grooves. I surmise that they were used individually, and not both at once.

The lead to wood rod intersection includes a copper joint pin. The wood to push/pull rod joint is reinforced by a brass collar.

The cutter was made of hardened steel with teeth oriented at 45 degrees to the bore axis. These teeth are symmetrical in that they would cut as well on the pull stroke as on the pull stroke. Cutter height was adjusted by paper shims.

Jim Everett