I've been to a point in my engraving where I need to upgrade to a Microscope...with that in mind I decided I had better have a new vise to go with it so that I'm not constantly messing with finding center.

Not being in any hurry since I needed to save up to buy a Microscope anyways and not being able to afford both a vise and a scope at the same time as well as not seeing a vise on the market that had all the features I want in a vise I decided to make my own. I've made all my other vises so it wasn't like I didn't have an idea of what I wanted to improve/change. I also didn't want to infringe on anybodies patents so I was careful to incorporate ideas that were either common across the industry or my own. Over the course of the last year on my one day a week off from building guns I've been slowly tinkering with building this thing a piece at a time...

So here it is:

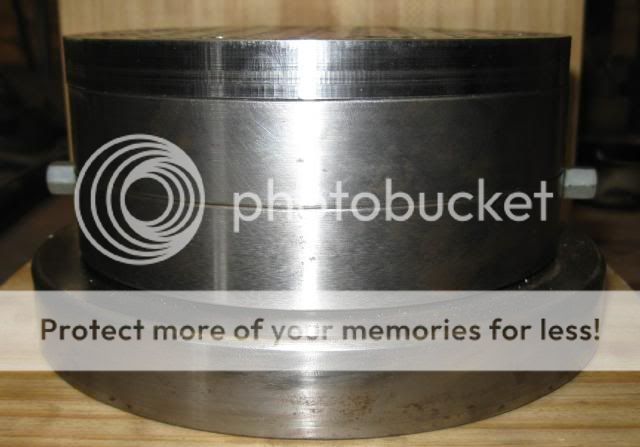

This is the complete vise with standard jaws on top:

Of course it needs to be able to tilt so I built the base with a bearing and a collar arrangement using a flange, threaded pipe and a pipe cap machined out to accept the ball bearing:

And of course when working under a scope it helps to be able to offset the head around the center of rotation so I built it to offset the width of the vise jaws when needed:

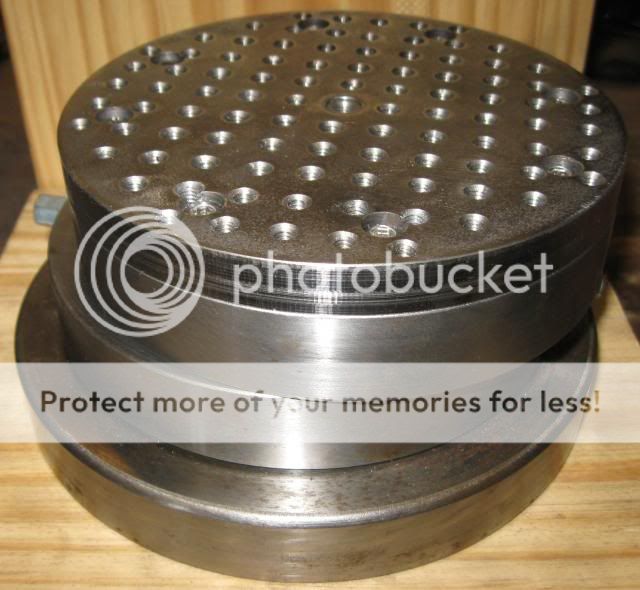

I've found that vise jaws can be so limiting in their holding ability so with that in mind one day I was working on my rotary table on my mill and noticed how easy it was to mount/clamp just about anything down with the clamping plate so I designed my vise to have removable jaws on a clamping plate:

This way I can fabricate just about any type of clamp or jig I need and have virtually unlimited ways to hold thing down to the vise.

Of course why stop there...by removing a few more screws I can take the vise off the base and tilt arm and have a low profile offset vise that can be used with a turntable or sine plate:

Some more views:

It's all carbon steel because that was what I had laying around my shop, I wish I could have made it out of stainless but this was built on a budget with a new microscope in mind.

It weighs 52 pounds with everything put together...it of course gets lighter as I start removing parts and pieces but even as a flat vise with out the base or jaws it still weighs 20ish pounds.

As time goes by and I know what kind of jigs and clamps I need I'll start fabricating them, probably mostly in brass to be non-marring. I figured I might start by making a simplified miniature set of bridgeport style clamps.

Any questions, comments, ideas, critiques are welcome.

Thanks for looking,

Colin