Hey, Mark, my work evolves, too!

Even though it looks like you are talking way too much, you are bringing up very good points. You're talking about finer points of the process, which sometimes are not conscious to me during the build. In other words, thanks for bringing this up.

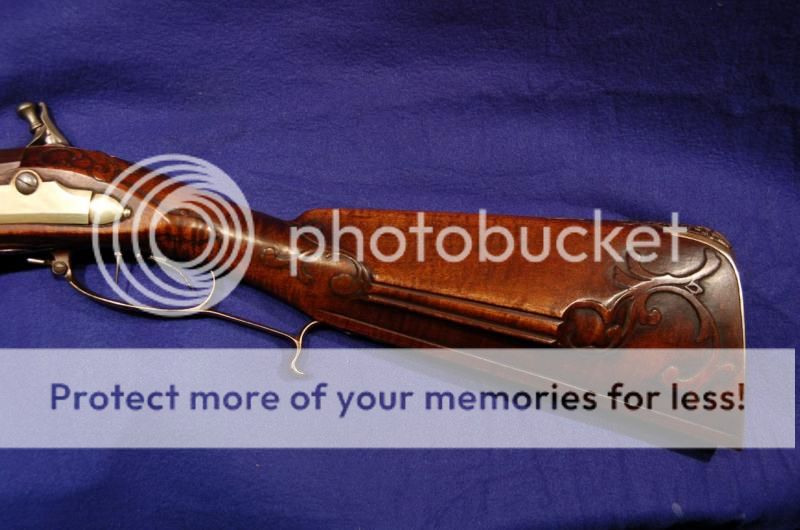

I agree, it's a process of working one area into another, until you decide it's done, or sick of it. While carving, as Mark talks about, I also do minor stock shaping. Stab the design, cut away background, then rasp and scrape everything smooth. At this point, I turn everything in a slanting light to see the contours. If I see a shadow line I don't like, or a hump or a hollow here or there, I scrape it to the proper contour.

cheekpiece in the early stages. I didn't know what size or where it was going to end up, so I left it large and long.

All those things happened with stock shaping, then carving, shaping, finishing.