Guys,

I have had a dream of making a flash hole chamfer tool just like the one used in the Colonial Williamsburg shop.

Or like the one from JHAT.

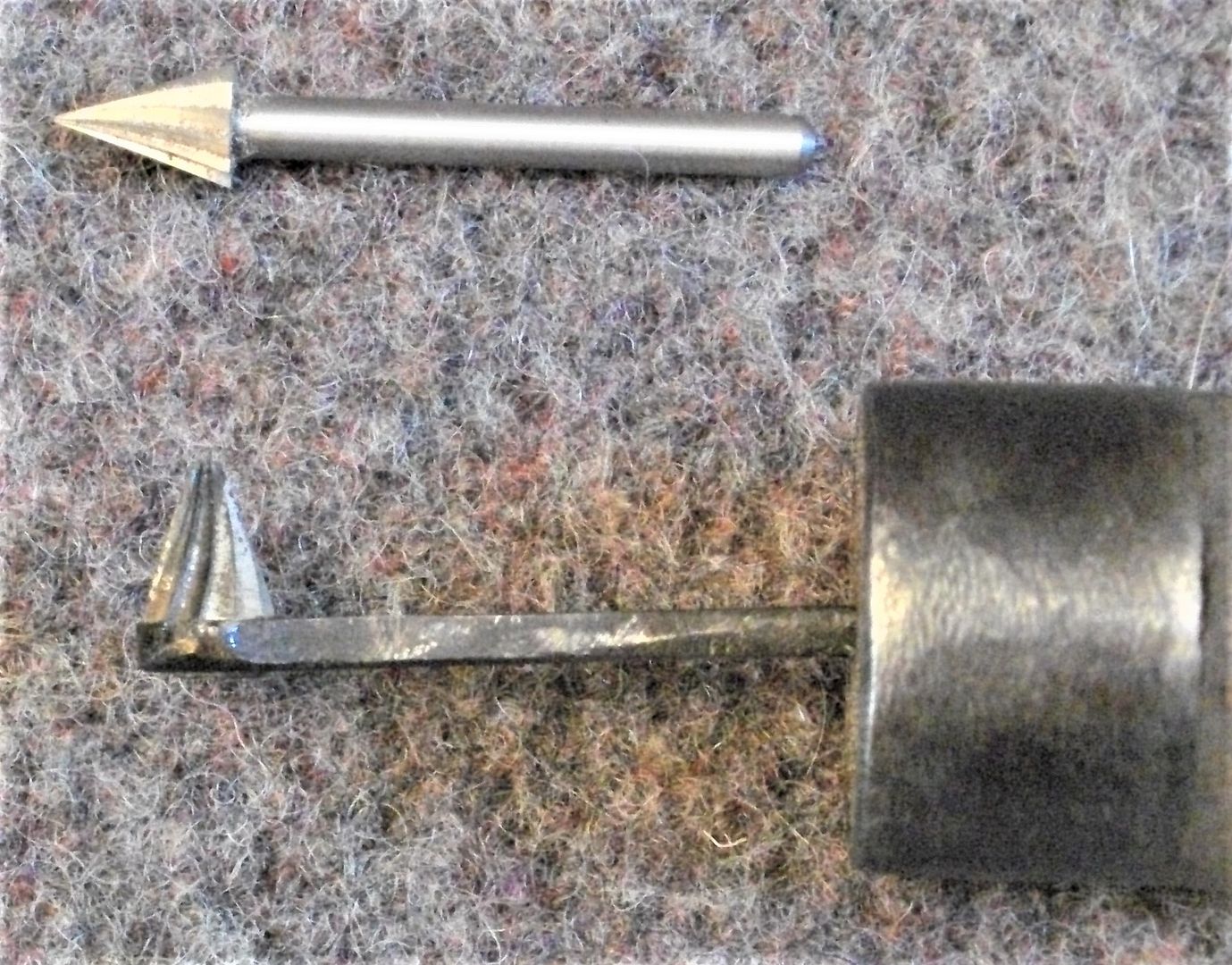

While these are really nice tools I felt that life is just too short to make a copy! So, I thought that there must be a more simple way to do this job. I found that there is a very simple and easy to make tool to chamfer the flash hole from the inside of the barrel. Here it is:

I simply bought a Dremel tool steel cutter bit as shown (they came two in a pack). Cut the shank down and epoxied it into a spring steel holder with a simple handle. I also ground off the very sharp tip of the cutter. It works easily by inserting the tip of the cutter into the interior of the flash hole and wriggling it back and forth - simple. I can get about a 90 degree swing with the tool. As with a file, push on the cut direction and relax on the return direction. It only takes a minute to cut a deep chamfer on the flash hole. The tool will fit into a bore as small as 0.410.

When planning to chamfer the flash hole I must position the flash hole (and the flintlock) about 1/10 inch forward from the breech plug face so as to not have the chamfer cut into the breech plug seat. I normally put the flash hole very close to the breech plug face, but now I put it a bit more forward - does this make sense?

Jim