I mentioned earlier that I think it is very helpful to make blueprints. I think that would be true even if you are working with a kit or a precarve. Many precarved stocks leave a little wiggle room, and if you wiggle in the wrong direction, things may not fit together as well as you had hoped. Better to plan things out carefully before cutting wood.

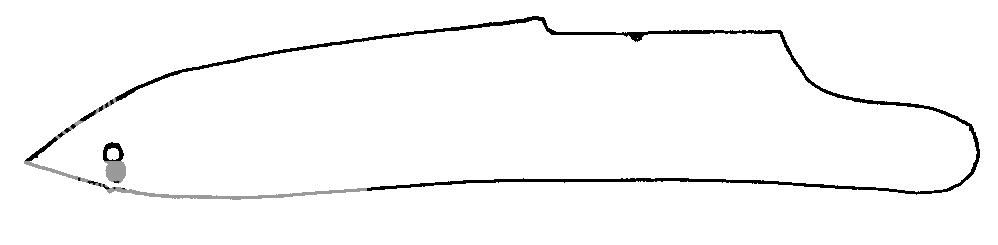

I find it helpful to draw up a full size blueprint by using full size tracings of the components. This first image shows a tracing of a small Siler. (I made this tracing using a plastic template that I made up some years ago. The plastic template has tic marks along the edge to indicate sear position and the touch hole position.) I have drawn in the positions of the sear armóboth the cocked position (black dot) and the release position (white dot).

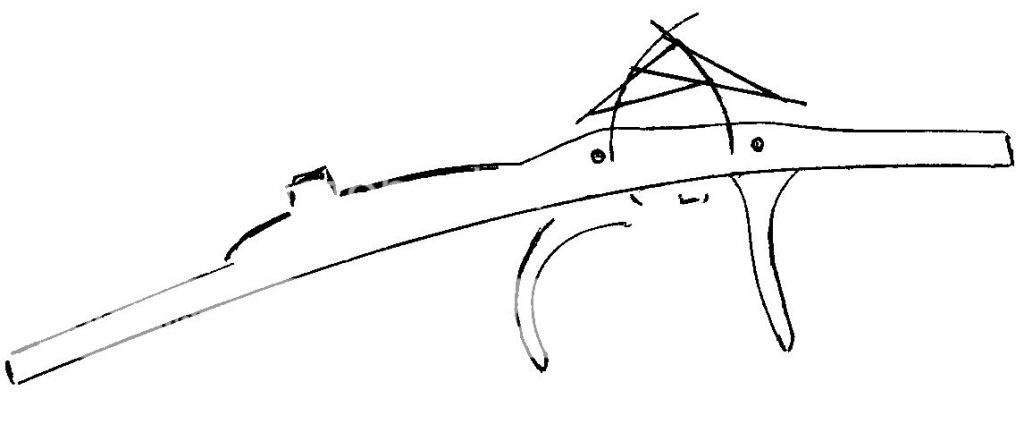

Next is a full size tracing of the triggers, with the relevant positions of the trigger bars and their arcs drawn in, so that I can identify the effective area (where the sear arm needs to sit).

I find it is helpful to make these tracings on individual pieces of paper, so that I can move them around on the blue print and position them were I want them. (That is to say that I do not try to draw them in place on the blue print.)

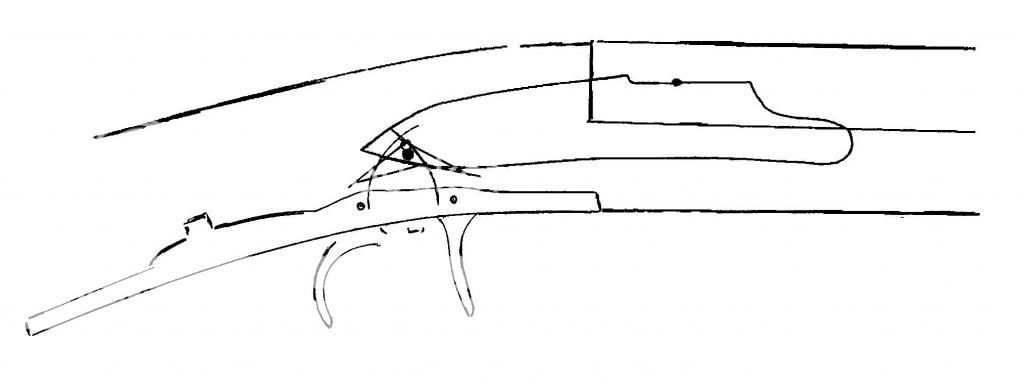

To make the blue print of the lock/trigger intersection area, I first trace the barrel breech area onto a big piece of paper. The barrel is the mechanical foundation of the firearm, so it goes first. The lock must be positioned in relation to where I want the touch hole, so I position the lock tracing on top of the tracing of the barrel. The trigger is then positioned so as to be sure the sear arm will be in the effective area.

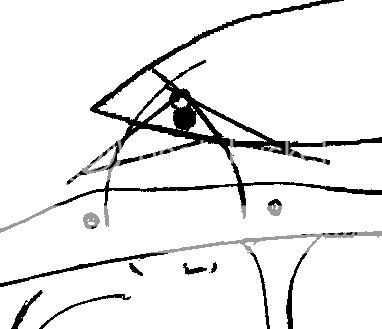

Hereís an enlarged view, so that you can see the intersecting area more clearly.

If building from a slab, then there is a bit of flexibility in the angle at which the components fit together. If working with a precarved stock or kit, there may be less flexibility, but the basic principles still apply. A plan like this allows you to know exactly where the trigger plate mortise needs to go so as to get the trigger and lock positioned properly.

This is just a sketch, so I have only shown the barrel, lock plate and trigger. In a real full size plan I would also draw in the main spring and bolster, the plug and tang, the trigger guard, rod hole, etc. The trigger plate profile must agree with the lower profile of the stock, but you can sometimes modify the plate a bit, provided you plan for it.

Let me also mention that I donít mean to suggest that a blue print necessarily needs to include all these lines, arcs, etc. But it's very helpful for a builder to understand how all these things work together, and sometimes the best way to get that kind of understanding is to plot it all out.