Hey Everyone,

A member asked me how I went about making a F&I style horn--so here it goes...

First, find as white a horn as possible--helps to bring out the scrimshaw. I know, sometimes this is a tough task at times!

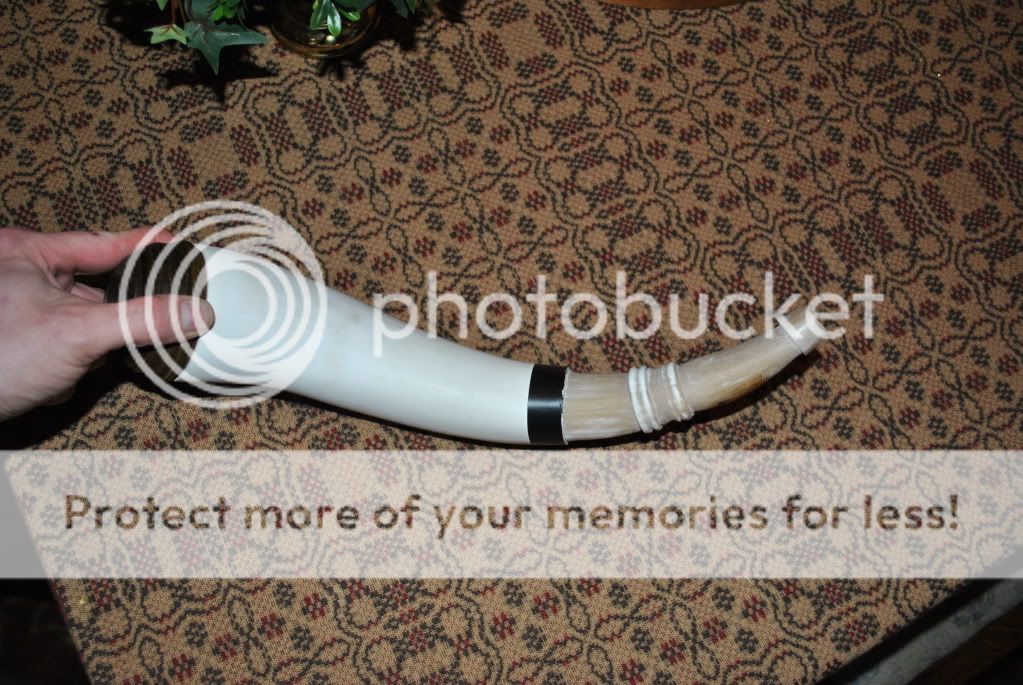

Here is the horn in the white, after I cut the tip (about 1 inch from where the internal cavity bottoms out at the tip) and squared the butt. I use a belt sander to square the end. The horn was very oval and it took a couple of heatings with varying types of sizers. If the horn is very oval, you may have to heat in stages with longer and thinner sizers working your way out to the largest at the butt section. Once it is round, I then turned the plug from a nice piece of maple--turned in the style of those from the period--there is no hard and fast rule--just look at a lot of examples. I will extensively work the the body of the horn--I find it really nice to put it on a sizer that is in my 4-jaw chuck attached to the headstock of my lathe (helps that it rotates 180 degrees. I can spin the horn around and file so that it is easier to round as you work it.

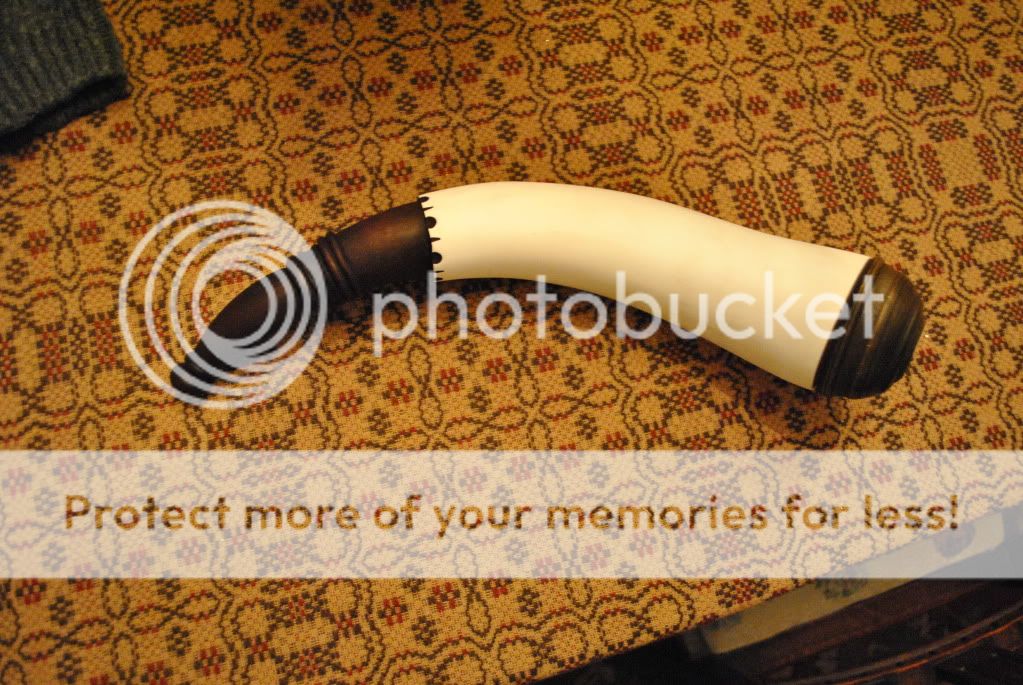

Below is the horn with the plug stained--I use Danglers dark walnut stain--alcohol based. Stained, then sanded with #0000 steel wool three times--stain, sand, stain sand... (you get the idea). The plug is not permanently attached at this time. You can see where I sectioned off where various parts of the spout will be carved--typically, you are looking for about 1/3 of the horn to be spout. This is not a hard and fast rule! Do some research and you will see what I am talking about--some spouts are non existant. 1/3 rule is just what looks good to the eye.

Here is the rough-shaped spout...I use a small xacto saw to cut the lines. Next, I wrap a piece of electrical tape around where the engrailing will go so that I don't accidentally tear up that portion of the horn as I work the spout. I then use various rasps to get the initial shape (look at any wood working store, flea market, or garage sales to pick up files. I also use an auto-body file to take off a lot of materials. Some folks use a chisel to take off layers of horn--key is to chisel away from the spout since horn grows in layers--think of a stack of Dixie cups (if you go the other direction, you will be going through the layers vs along with the layers). Make sure that when you are filing the horn that you are keeping an eye on the "lines" of the horn so that the spout flows from the engrailing through to the tip.

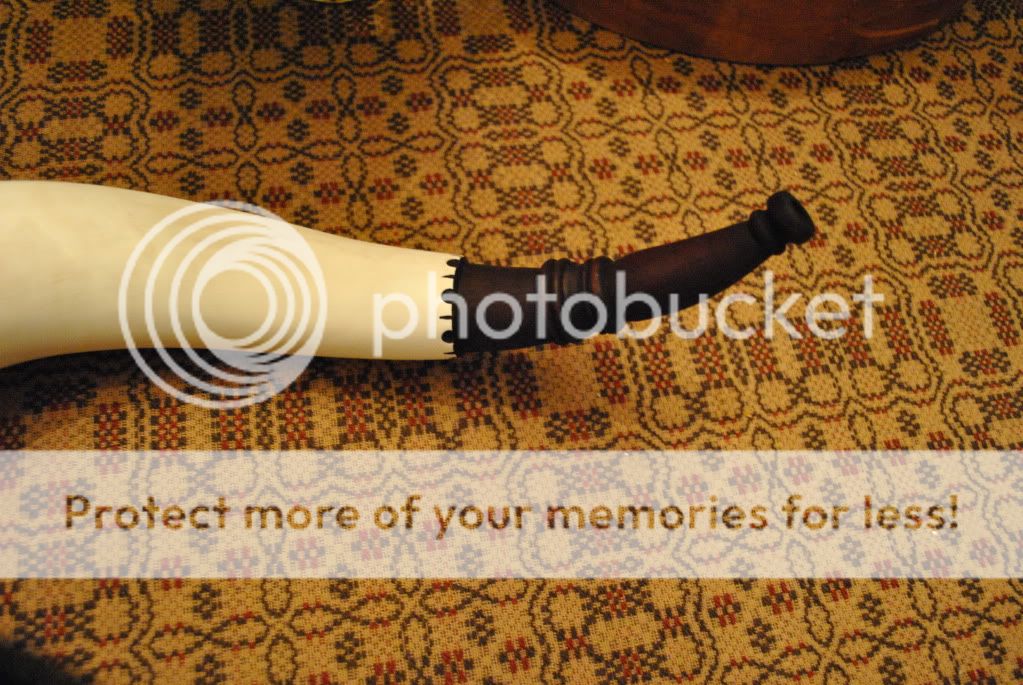

Now the spout is further shaped using very fine needle files... I will use wet/dry emery cloth to sharpen the edges and take out the file marks (a sanding sponge is a good to get into the nooks and cranies and round over some beads. I will then pick a design for the engrailing--personal choice here. I will use wood chisels or even a rotary tool to make the pattern.

Here the spout is dyed. Before dying, I have a simple trick--I use electrical tape wrapped near the engrailing and wound up the horn towards the butt section and back down to where I started. The tape wrapping is a huge time saver since it prevents the dye from coloring too much of the horn--that means I don't have to spend the next hour removing the dye from the horn! I use a package of dark brown Rit dye with about 1 tsp of black and a splash of white vinegar. The vinegar fixes the dye so it will retain its color. I believe in colonial times it is referred to as a "mort."

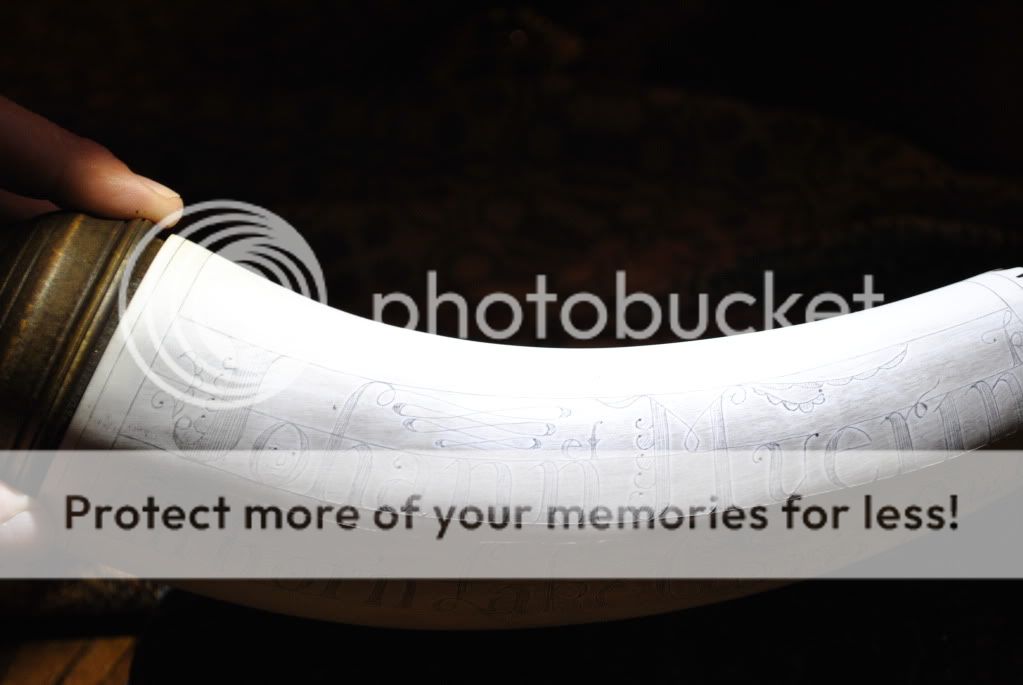

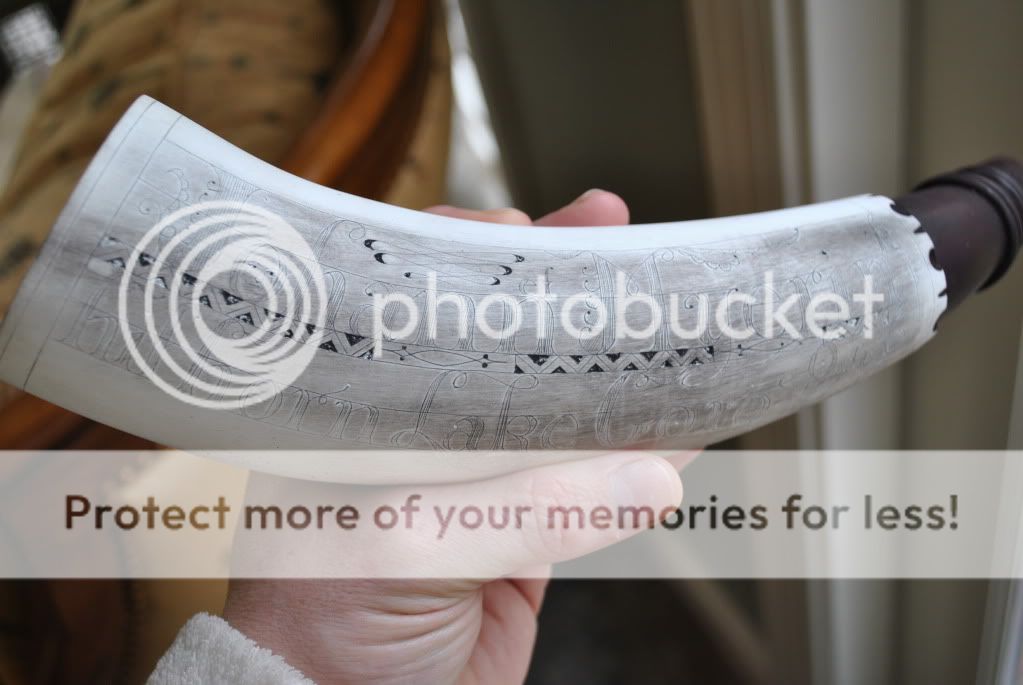

Before doing any scrim work, I will do a lot of research--I really like the work of John Bush and other artists from the Lake George school, so I gravitate to his style. I will pick the lettering style and overall design. This design is for a friend and is a relative. To make the lines as straight as possible, I will go back to the electrical tape so that the lines are sharp. It also can be stretched so that I can follow the shape of the horn--this is important so that the lettering maintains the same height along the length of the horn. Before drawing the lettering, I will take the horn to the copy machine and make a couple of pics of the horn so that I can figure out the layout of the lettering without having to draw on the horn. Then I just mark off where major sections of the horn--like first & last name--will be. Keeping the Xerox pic nearby, I begin lining everything in--just concentrating on the outline of the lettering--detail work will come later. After outlining, I will use a good art gum eraser so that I can see exactly where I cut into the horn. Below is after the letters were lined then filled in. There is a little bit of detail work, but a lot left to do.

Here is the completed name section of the horn. Typical of John Bush's work is the chip-carved saw tooth pattern. To this point, I have not inked the design in. I like to use powdered tempera paint to highlight the lines of the design. Just put a little on your finger and rub over the line. If the design has chip carving--like the saw tooth--the paint will not get into the bigger carved areas. Not a big deal as I use it just to give me an idea of where my lines are and to get an initial look at how the design is turning out.

MORE WORK TO COME!