I'm posting this in hopes someone will find it helpful. It is a part of building a TN rifle I found to be a daunting task when I started out.

I still remember the disappointment I felt when I poured all the parts out on the counter and saw the springs that were included with my banana patchbox. Uuugh! They looked nothing like the ones I had seen on originals. I read through the archives and found nothing that helped. Just verbal descriptions which may as well been Greek to me at that point.

Let's start with the spring that pops the door open. I use an old hacksaw blade. You can rough cut it with a pair of tin snips and then grind it to shape or just grind it. Heat it up with a propane torch and make your bends with it red hot. I like to use the end pieces. The hole that is already there comes in handy and will save you a step. This is a fancy one compared to most I have seen.

Here's the spring bent to shape and inlet so the lid screw holds it in place. Set it aside until we are ready to temper.

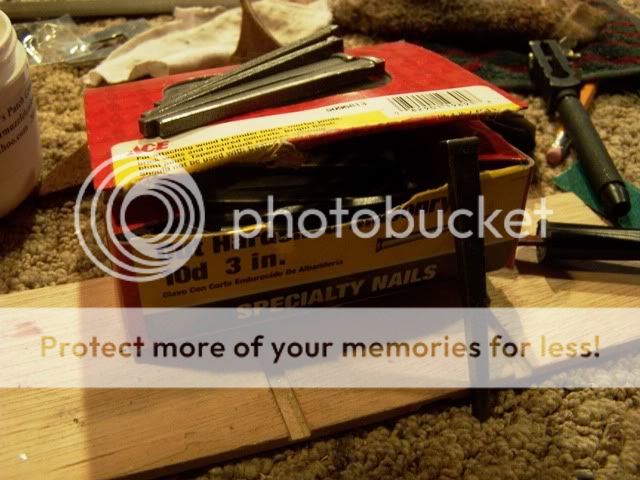

Now for the one that scared me> Not because it is hard to make but because there are no pictures if what it looks like. Start with a 10d, 3" masonry nail. You can use about anything that is spring steel. Old broken files work well too.

You want to anneal the steel by heating it cherry red and then letting it cool. I have a small pan of sand I keep by the bench for burying parts in to let cool.

Picture to come

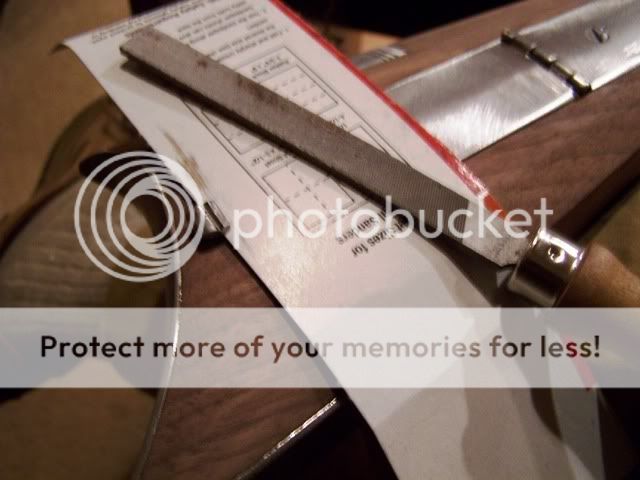

Start working the shaft down to nail size. You can grind it, file it or even heat it and forge it out if you want. I grind the bulk of it away and then file it the last bit.

This shows nails in various steps of being worked down.

More pics

Notice the final one has a groove filed in it for your nail to catch and work the latch.

It may not be necessary but I take a small chisel and make some little spurs that stick out and hopefully will grip the wood better.

How's this compared to the kit springs?

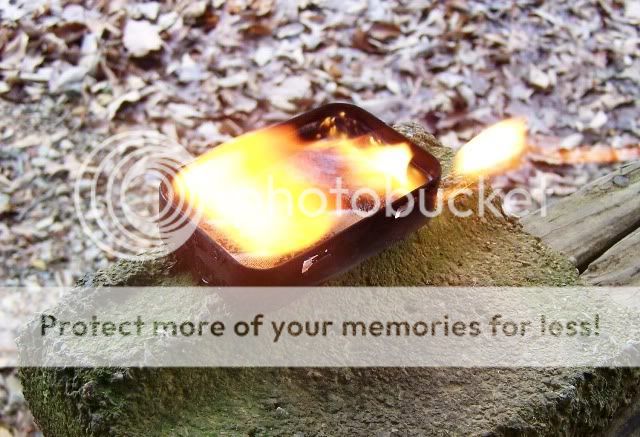

Now time to temper. Heat the spring with a propane torch till cherry red and quench. I use motor oil. Once you have done this do not try to bend them. They will break for sure. To temper get a small Altoid or sardine can and cover the spring with motor oil. I use a propane torch to light the oil. Let it burn until the oil is gone.

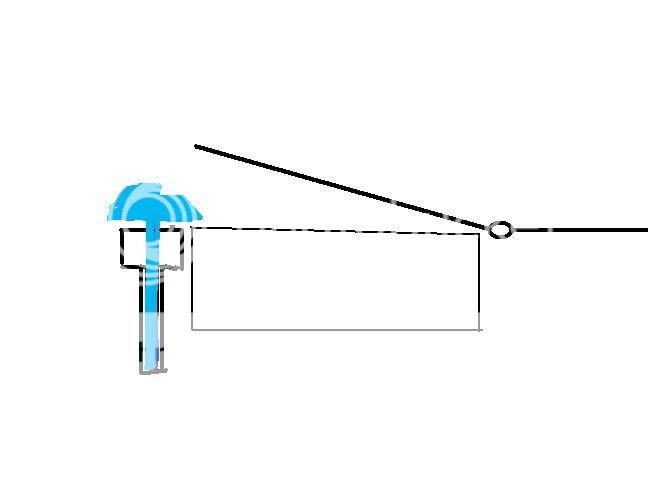

Now, for the hole. Carefully measure where the nail shaft would need to go to just barely catch the lip of the box lid. You will drill a hole 1/16" here. This is your pilot hole. Maybe 1" deep but measure your stock and make sure you don't drill out the other side. Find a drill bit with the diameter just smaller than the head size and drill a larger hole about 1/2 the depth of your first one. This gives the spring space to move. If you are not sure about the depth. Clamp the spring in a vise and you can see how far down the shaft it should be to let the spring move.

You are ready to take the plunge and drive the nail in.

Stop just short of having it down on the lid and you can see if it needs to be adjusted. If it does, place a piece of cardboard or sheet brass underneath to protect the gun and file away. Don't count of doing a lot of adjusting if your spring has been hardened right.

If you have done everything right, with very little pressure you box lid should pop right open with a little thumb pressure and snap back in place without touching the lid spring.

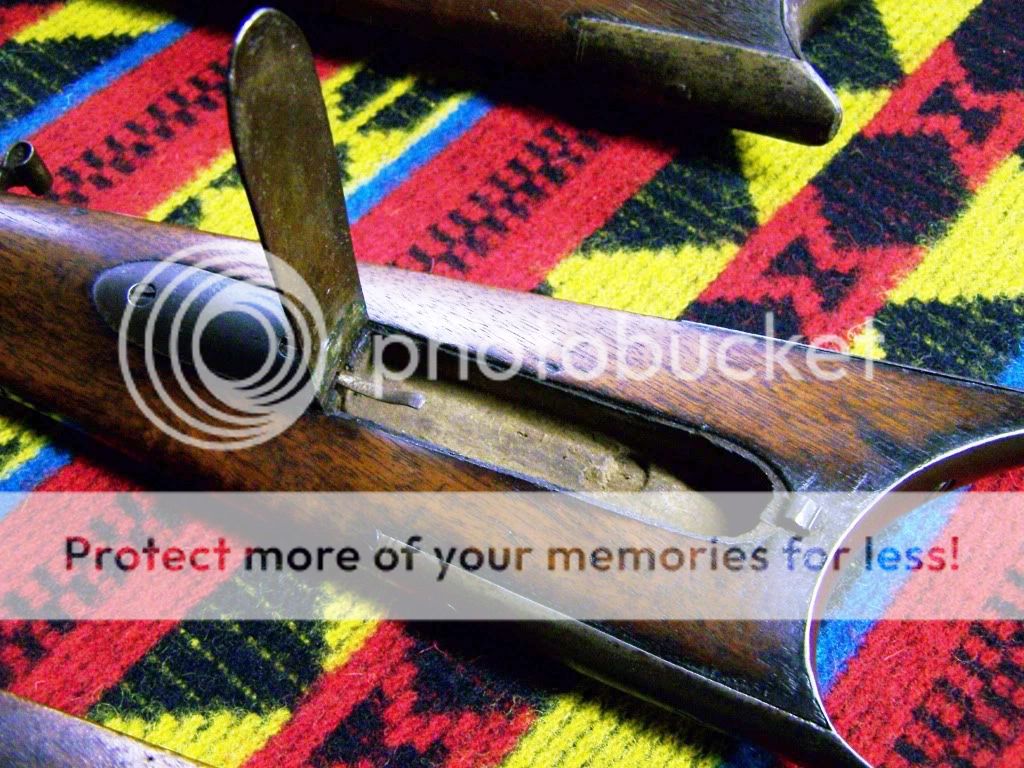

Here's a picture of the inside of an upper E. TN patchbox.

For comparison, here's a picture of the insode of a Soddy-Daisy patchbox. Notice the difference in door catch springs.

I hope someone finds this helpful.

Cheers,

Ken