Pierce,

In the photo it looks like you had your flint in there without any leather around it, and without it touching the shank of the jaw screw. Most of us get our best sparks if we use a piece of leather with a hole in the middle, with the leather wrapped around the flint, and the flint slid back so that it rests against the screw shank. The leather helps the jaws grip the flint. The hole in the leather allows the flint to directly contact the screw shank. If the flint is not sitting directly against the screw shank, then the leather just becomes a shock absorber, preventing the flint from digging in adequately.

You may also want to file the front edge of the jaws, especially the top jaw, so that the metal of the jaws slope down to a thinner edge. That helps keep the top jaw from hitting the frizzen as the flint slides down the face of the frizzen.

The stiffness in the release could be because of one or combinations of things. Common problems include:

1. the angle of the full cock notch,

2. the full cock notch is too deep,

3. the face of the notch is not adequately smooth, such that the sear gets stuck in the rough surface,

4. the tip (nose) of the sear is too flat (A thin, rounded sear tip will work more smoothly, as it allows the face of the notch to slide over the tip as if moving through a series of tangents. In contrast, a flat edge will require the tumbler to be pushed away (rotated away) from the tip as the sear is released.)

5. a poorly fitted sear screw, such that the sear doesn't pivot efficiently on the screw,

6. two strong a sear spring,

7. the tip of the sear spring isn't polished, or the top of the sear isn't polished, so that the spring is grabbing or digging in rather than sliding as the sear is raised,

8. the lower arm of the sear spring is too long, so that as the spring is compressed it binds against the sear. (The lower arm should have some length, as that contributes to a smoother action, but that length has to be positioned correctly. A V spring normally has a downward curve added to the lower arm--that's called a "pre-load". As the spring is compressed that bend straightens out, effectively making the spring slightly longer, straight line measurement. So, if the tip of the spring is already sitting right against the bump in the sear body where the screw passes through, then there is no room for that added length when the spring straightens. So sometimes it's necessary to file a few thousandths off the end of the spring, and polish both the bottom edge of the spring that rides on the sear, and also polish the top of the sear at that engagement area.)

(There are a few other issues that sometimes cause trouble, but these are common.)

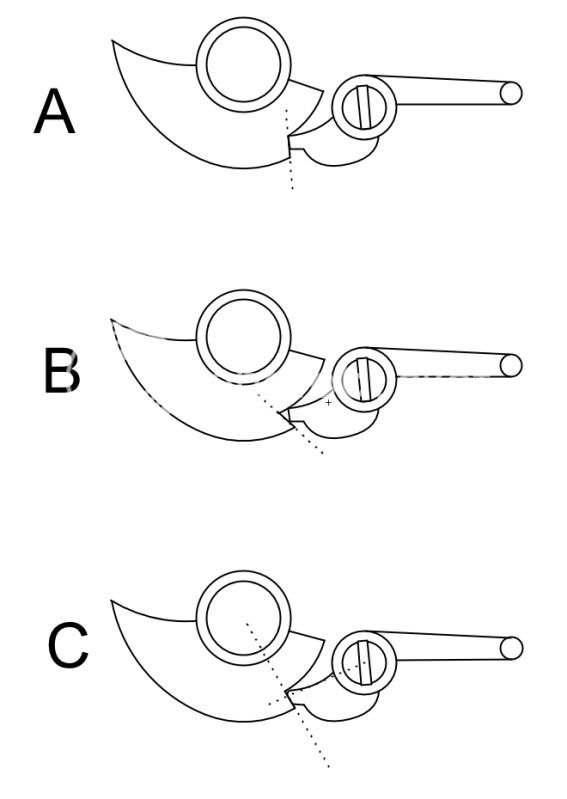

Regarding the angle of the notch, here’s a link and excerpt from an old post discussing full cock notch geometry. You may want to read that thread, but I wanted to show you the diagram from Acer, in particular.

https://americanlongrifles.org/forum/index.php?topic=20505.msg193894#msg193894Here's what I'm trying to say, in picture format.

A will pop right out of cock without a sear spring to hold it in.

B will require lots of effort to trip the sear.

C is neutral as far as angles. It's what I try for when I tune my locks.